High Quality Drilling Rig Undercarriage Parts

Drilling Rig and Piling Rig Undercarriage Parts Specialist

ALWAYS BE CUSTOMER-ORIENTED!

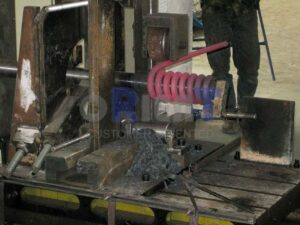

Drilling Rig Undercarriage Parts – track shoe, track chain assembly, track roller, carrier roller, sprocket, idler. Various brands & models are available.

Quality Drilling Rig Undercarriage Parts

About Us

YANTAI ORIENT HEAVY INDUSTRY TECHNOLOGY CO., LTD.

We specializes in the production of UNDERCARRIAGE PARTS for drilling rig, mining excavator, mining bulldozer, crawler crane.

Our main products are TRACK SHOE, TRACK CHAIN, TRACK ROLLER, CARRIER ROLLER, SPROCKET, IDLER and TRACK GUARD, which are cost-effective and suitable for Bauer, Liebherr, Soilmec, Atlas Copco, Casagrande, IMT, CMV, Mait, Sandvik, Delmag, Sany, XCMG, Zoomlion, Sunward, etc.

We always be customer-oriented.

What’s more, with the advanced equipment, skilled technology, and high-quality raw material, our product has excellent performance and quality. Nowadays, with continuous development, our products have been sold to more than 30 countries worldwide and have received satisfaction from over 1000 customers. We always sincerely with each customer for long-term cooperation.