Drilling Rig Maintenance Skills

1. Hydraulic Parts

Replace the hydraulic oil, return oil filter element, and pilot filter element according to the specified maintenance cycle, and check if there are any adsorbed iron or copper chips on the filter element.

When using a crusher, the deterioration of hydraulic oil accelerates, and the replacement cycle should be shortened.

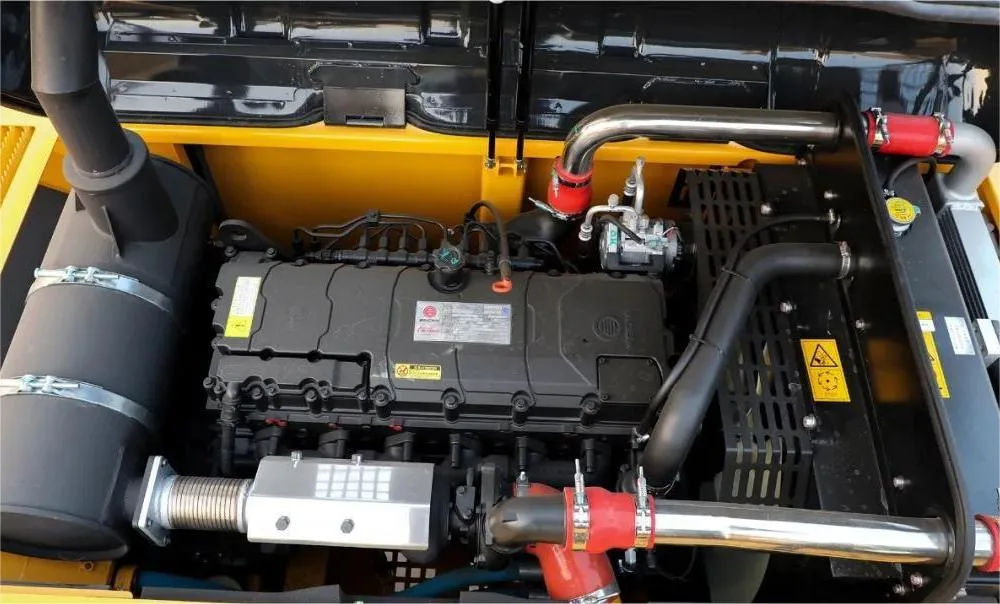

2. Engine Parts

The engine oil and oil filter should be replaced according to the specified maintenance interval. Diesel fuel should be provided by regular gas stations and filtered before refueling. Before starting work every day, drain water at the bottom of the diesel tank and at the oil-water separator.

The drilling rig cannot be operated without oil for a long time, and should be refueled in a timely manner. After replacing hydraulic oil or hydraulic components, timely exhaust the air.

3. Mechanical Parts

Regular replacement of gear oil is required for slewing bearing reducers and walking reducers.

Want to replace the walking undercarriage parts: https://drillingtrackparts.com/products/

Pay attention to cleaning up soil and debris on the pin, and add lubricating oil in a timely manner. When wading, if the water overflows the slewing bearing gear ring, the lubricating oil inside the slewing bearing gear ring should be replaced in a timely manner.

At the same time, pay attention to the rust prevention of the cylinder rod. When parking for a long time, it is necessary to apply lubricating oil to the exposed metal parts to prevent rusting.

4. Electrical Parts

Pay attention to waterproofing, do not work in deep water areas, and do not directly flush electrical components with water during cleaning.

Do not stack debris, especially metal tools, in the battery box as it can easily cause a fire.

Do not replace insurance with iron or copper wire, nor replace it with non compliant insurance.

When the drill rig is parked for a long time, remove the battery cable to prevent power loss.

5. Machine Structure

Check pins and bolts every day, observe for any looseness, detachment, or missing, and tighten them in a timely manner.

Check the structure daily for cracks and deformations.

When parking the piling rig, attention should be paid to the surrounding environment. It is recommended to park it on a solid and stable hard ground, and not on rivers, cliffs, or slopes to prevent accidents.

More Drilling Rig Maintenance Skills: https://www.facebook.com/YantaiOrient