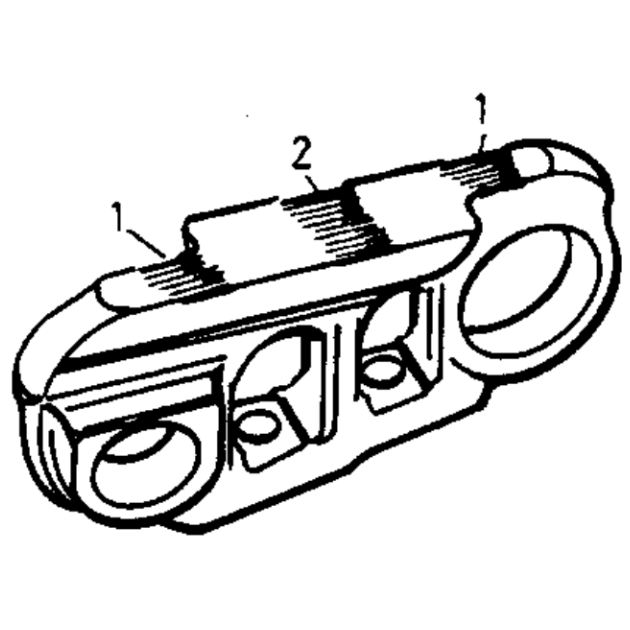

1. Uneven or Scalloping Wear of Track Link

Scalloping wear of track link is normal for high speed machines with high mileage.

- Causes

End scallops (areas #1) are caused by the reduced surface area where the links overlap, this situation increases specific pressure and thus the wear rate.

Pitch extension due to internal wear of the joint increases this effect.

Center wear (#2) is due to the reduced contact area between the link flat surface and the curved idler tread.

- Accelerators

Speed, weight, horsepower, impact, abrasiveness, shoe width, track tension.

Machines equipped with two idlers instead of one display faster wear.

- Effects

Premature wear in the area above the pin boss reduces wear life of chain.

Machine vibrates and moves from side to side during transportation.

- Remedies

Equip the machine with a sealed and lubricated track (SALT) chain (if not already present).

Maintain proper track tension.

2. Rail Side Wear of Track Link

Heavy wear at transition from link top to link side.

Can be found inside and/or outside the link.

- Causes

Contact of the links against roller and idler flanges.

This situation can also be caused by fitting a new track chain on an undercarriage with heavily worn rollers. In this case the wear pattern of the rollers is transferred onto the track links ( bow type wear ).

Misalignment of one or more components of the undercarriage. Track chain is

forced in line by roller flanges.

- Accelerators

Same as “Uneven or Scalloping Wear” plus turning speed, extremely large track shoes when operating on high impact terrains.

- Effects

Reduced wear life because of increased specific pressure.

New rollers wear faster if installed and operated with a worn track chain.

- Remedies

Replace all undercarriage components at the same time.

Reduce controllable variables as far as possible by using narrower track shoes alternating work directions on sidehills and checking U/C alignment.

Also snaky track chains should be replaced.

3. Rail Inside Gouging

Wear on internal side of the link concentrated on one or more points at regular intervals.

- Causes

Interference between the link and sprocket tooth tips, due to:

- Misalignments between track and sprocket;

- Snaky chain during steering actions;

- Use of incorrect sprocket.

- Accelerators

Sidehill operations with wide track shoes

- Effects

Reduced reusability of links and sprockets

- Remedies

Eliminate misalignments and use shoes with the proper width.

Use track guides.

Use the proper sprockets.

4. Elongation of the Counterbore

Extension or ovalization of the bushing counterbore

- Causes

Rotation of the bushing in the link as a direct result of a pitch extension.

This can also be due to a seal failure that will result in internal seizure.

- Accelerators

Wide track shoes.

- Effects

Reduced re-usage of the links, even with new seals.

- Remedies

Turn pins and bushings at the service limits.

Avoid sudden speed variations.

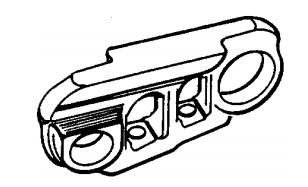

5. Pin Boss Wear of Track Link

Wear on the bottom side of the link pin boss

- Causes

Contact between the pin boss with the top of the roller flange due to the fact that the wear life of the roller treads and link wear surface has been exceeded.

- Accelerators

Concentrated and uneven loads on the first rollers (front or rear) of the undercarriage, for causes attributable to the application.

- Effects

Reduced pin retention resulting in possible machine downtime and further damage to other undercarriage components.

Re-usability of links with pin and bushing turn or rotation (servicing) and chain rebuilds are precluded.

Vibration in high-speed applications.

- Remedies

Monitor wear of undercarriage components and service/replace worn-out parts in good time.

Compensate for high loads on front or rear of machine by using counterweights.

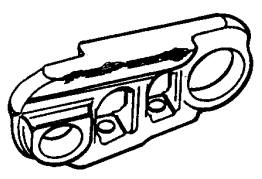

6. Rail Spalling

Chips detaching from side of the link rail.

The link should be considered affected by this problem only if the total length of spalling is longer than 30% of the total length of the link. Otherwise, the damage can be classified as purely superficial (and/or “cosmetic”).

- Causes

Normally caused by heavy impacts between the link and the roller treads and flanges.

This could also be caused by fitting a new chain on an undercarriage equipped with worn rollers. In fact, the high specific pressure due to the very small contact area work hardens the surface of the link corners. At the same time, it generates micro cracks below the surface at the level of the maximum stress concentration. These cracks propagate and will result in detachment of a chip of steel in a relatively short period of time.

- Accelerators

Excessive track tension, wide shoes, impact, machine speed and weight.

- Effects

Reduced wear life; re-usability.

- Remedies

Avoid installing new track chains on rollers with heavily worn treads.

Reduce or eliminate the effects of controllable variables like shoe width and track tension.

Thanks very interesting blog!