How to Solve the Problem of Surface Wear on Sprocket Wheel?

Tooth Root and Side Wear on Sprocket

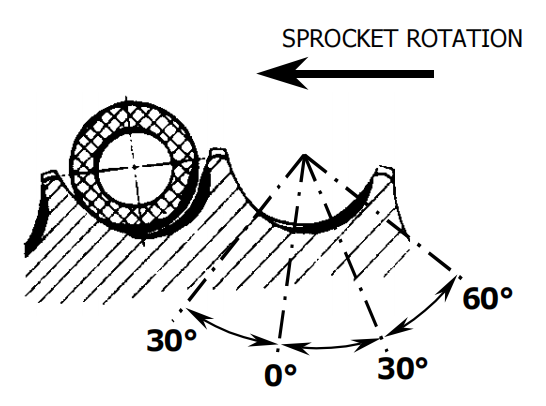

From 0 to 30 degrees from vertical (both directions); this is the normal expected wear pattern in the absence of severe packing and prior to significant pitch extension due to internal wear of the track joints.

The additional 30 degrees on the side of the tooth (from 30° to 60° from vertical) represent the normal expected wear pattern for track chains displaying a certain pitch extension and/or used in moderate packing conditions.

With some exceptions, in practical daily usage of the machine, it is impossible to avoid either of these kinds of wear.

Therefore, these situations must be considered as “normal”.

Causes

- Root wear is mainly due to sliding bushing movement from one tooth profile to the other during forward to reverse direction changes (and vice-versa). Slight pitch mismatching and minor packing effects must also be included.

- Drive side wear is caused by a moderate degree of packing plus some increase in the link pitch, or both these factors together.

Accelerators

One of the major accelerators is an overtightened track.

Worn rear rollers, wide shoes and reverse loads.

Machine weight, engine power and speed; impact, soil abrasiveness.

Mud relief sprockets/segments increase the specific pressure on the tooth root thus increasing root wear proportionally.

Effects

If the pattern consists only of root wear, it must be considered “normal” wear.

Side wear reduces the wear life and eventually the strength of the tooth in the driving position.

Remedies

Reduce or eliminate accelerator variables, change sprockets/segments at 100% wear, install sealed and lubricated track chains in order to minimise internal wear.

Due to the cost of the components, the actions taken should be in consideration of the effects on the bushings.

Reverse Drive Side Tip Wear on Sprocket

This can be the most severe wear affecting sprocket teeth and bushings.

Due to undercarriage design, when the tooth engages the bushing at about 12 o’clock, these two parts are subjected to rotating sliding contact.

This rotation does not normally occur in forward travel.

Causes

Mislocation of the bushing due to large amount of packed material in the tooth root.

Internal wear of the joints that increases the link pitch.

Back jamming of the track chain due to incorrect track tension.

Accelerators

Machine speed, load and horsepower.

Impact and abrasiveness.

Uphill reverse loading of the machine with loose tracks.

Effects

Reduced wear life, need to adjust track tension more frequently.

This situation could also affect reusability of the bushings at service (wet turn).

Remedies

If caused by packing, reduce or eliminate controllable variables. In this case keeping track tension properly adjusted at all times will have a beneficial effect.

If operating constantly in extrudable packing material, installing the mud/snow sprockets/segments could help. As well as the use of shoes with centre holes (or relief holes).

If caused by excessively loose track chains, correct track tension.

Install sealed and lubricated track chains in order to minimise internal wear.

Forward Drive Side Tooth Tip Wear on Sprocket

Wear of the tooth tip in forward travel.

Like “Reverse Drive Side Tip Wear” but less severe tooth wear.

This is thanks to the fact that the relative rotary friction of the bushing against the tooth occurs at engagement “exit”(12 o’clock). At this stage the torque applied on the joint is relatively low.

This phenomenon is always accompanied by “Reverse Drive Side Tip Wear”

Causes

Same as “Reverse Drive Side Tip Wear”.

Although this is not a particularly critical factor, it could become a real problem in the case of track chain overtightening.

Accelerators

Same as “Reverse Drive Side Tip Wear”.

Effects

Same as “Reverse Drive Side Tip Wear”.

Remedies

Same as “Reverse Drive Side Tip Wear”.

Side or Facial Wear

Wear of the sprocket/segments side face.

This type of wear is generally not a factor considered in the evaluation of sprocket wear and replacement.

Causes

Sidehill operations.

Lack of track chain guidance.

Snaky track chains.

Back jamming of the track chain due to poor track tension.

Misalignment of sprocket/segments or rear roller; rear roller flanges worn-out.

Inward bending of track guiding guards.

Sprocket/segments wider than the track chain.

Accelerators

Frequent or sharp turns.

Machine speed, load and horsepower.

Impact, abrasiveness, uneven terrain.

Excessively wide shoes.

Effects

Link side wear.

Reduced contact area between bushing and tooth may increase specific pressure, thus increasing the wear rate.

Off-centre bushing wear.

Remedies

Replace the snaky track chain or turn pins and bushings.

In view of the cost of these components, the actions taken should be in consideration of the effects on the track, not sprocket wear.

Correct misalignments.

Replace track guiding guards, or the wear strips.

Tooth Corner Breakage or Gouging

Breakage of the inner and/or outer corners of the teeth.

Causes

Worsening of the causes of “Side or Facial Wear” can generate this problem.

Accelerators

Same as “Side or Facial Wear”.

Effects

Severe structural damage of links (gouging).

Track jumping.

Link side wear.

Off-centre bushing wear.

May increase wear rate.

Remedies

Same as “Side or Facial Wear”.

If you have any inquiry of undercarriage parts, please feel free to contact us.

- Email: info@heavyindustryparts.com

- Alibaba: https://ytrtzg.en.alibaba.com/?spm=a2700.shop_cp.88.12