How to Use Wire Rope for Piling Rig Correctly?

1. Wire Rope Deconvolution

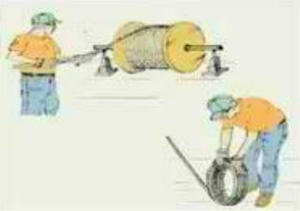

The unwinding and installation of steel wire ropes should be carried out using the correct method to prevent them from twisting. In addition, it is also important to avoid getting sand and soil on the surface of the rope. In order to avoid exacerbating wear and affecting the service life.

2. Wire Rope Cut Off

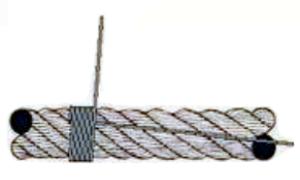

If the entire coil of wire rope needs to be cut off during use, the end should be bound or fused.

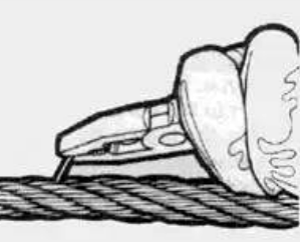

3. How to use wire rope clip?

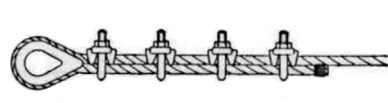

When the rope clamp must be installed, it should be fixed according to the method shown in the following figure. The spacing between rope clamps is 5-6 times the diameter of the rope.

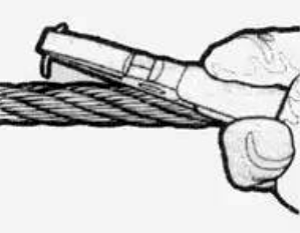

4. Selection of wire rope lay direction:

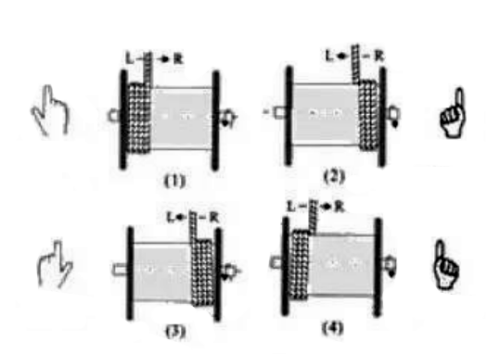

The winding method of the rope at the bottom of the drum should comply with the following figure.

5. Winding the Wire Rope

When winding the rope on the drum, it should be arranged neatly and cannot be wound randomly. Otherwise, it will cause serious compression damage to the wire rope during operation, affecting its service life.

6. Use of New Ropes

The use of new ropes must be ‘worn in’ under light loads. This can improve the service life of ropes. During use, excessive impact loads should also be avoided from causing damage to the rope.

7. No Excessively Release

During use, special attention should be paid to accurately calculating the distance during the drilling process and not excessively releasing the rope. To prevent the wire rope from intersecting in a relaxed state, which can cause structural damage and result in the entire rope being scrapped.

8. Rope Biting Treatment

For equipment with multiple layers of winding, it is inevitable for the wire rope to “bite” during use. It is recommended to regularly inspect the “bite rope” area during use and strengthen lubrication, or regularly “cut the rope” and stagger the “bite rope” area.

9. After the wire rope is put into use, its performance will gradually decrease.

Therefore, after using the new rope for a period of time, it is necessary to regularly inspect the parts of the rope that are prone to damage. For example, the parts where the rope “bites”, the lower layer of the rope on the drum, and the parts where the wire rope passes through the pulley and enters and exits the drum during severe impact. Provide a basis for the reasonable and safe use of wire ropes through regular inspections.

10. Wire Breakage Treatment:

When the wire still needs to be used due to wire breakage, the broken wire should be promptly treated. You can use pliers to clamp the broken wire and repeatedly bend it back and forth until the wire breaks. After such treatment, the broken end of the steel wire will be clamped between the strands and ropes, without causing any harm to the use of the steel wire. When the number of broken wires in one lay reaches 10% of the total number of outer steel wires, the steel rope must be replaced.

11. Recommendation:

The working method of rotary drilling rig is single rope lifting, which means that the steel rope has a free rotating end during operation. For safety and convenience of operation, priority should be given to using anti rotation steel ropes when purchasing.