Rotary drilling rigs are essential in various industries, including construction, mining, and oil exploration. Mastering their operation requires an understanding of techniques, safety measures, and maintenance practices. Here’s a comprehensive guide to help you become proficient in using rotary drilling rigs.

Understanding Rotary Drilling Rigs

Rotary drilling rigs utilize a rotating drill bit to penetrate the earth’s surface. They come in various types, including:

- Top Drive Rigs: Utilize a motor mounted on the rig’s top to rotate the drill string.

- Cable Tool Rigs: Use a heavy drill bit that is raised and dropped to break rock.

- Rotary Table Rigs: Employ a rotary table to turn the drill string.

Each type has its specific applications, advantages, and operational techniques.

Key Tips for Effective Operation

1. Pre-Operation Checks

Before starting any drilling operation, perform thorough pre-operation checks:

- Inspect Equipment: Ensure all components, including the drill bit, mud pumps, and power sources, are in good condition.

- Check Safety Gear: Confirm that personal protective equipment (PPE) is available and in proper condition.

- Review Site Conditions: Understand the geological conditions of the drilling site to select the appropriate equipment and techniques.

2. Proper Drilling Techniques

- Select the Right Bit: Choose a drill bit that matches the geological conditions to enhance efficiency and reduce wear.

- Control Weight on Bit (WOB): Adjust the weight applied to the drill bit for optimal penetration rate without causing damage.

- Monitor Rotation Speed: Maintain the right rotation speed based on the type of rock and bit being used.

3. Efficient Fluid Management

Drilling fluids (or mud) play a critical role in the drilling process. They help cool the bit, carry cuttings to the surface, and stabilize the borehole.

- Choose the Right Fluid: Select a drilling fluid that suits the geological conditions and the type of drilling being conducted.

- Monitor Fluid Levels: Keep an eye on the fluid levels in the mud pits to ensure a continuous supply during drilling.

- Adjust Viscosity: Maintain the right viscosity of the drilling fluid to ensure efficient cuttings removal.

Safety Practices

Safety is paramount in any drilling operation. Adhere to these practices to minimize risks:

- Regular Training: Ensure that all personnel are trained in safe operating procedures and emergency response.

- Emergency Equipment: Keep fire extinguishers, first aid kits, and spill containment materials readily accessible.

- Establish Clear Communication: Use hand signals or radios to communicate clearly among team members during operations.

Maintenance and Troubleshooting

Regular maintenance is essential to ensure the longevity and efficiency of rotary drilling rigs:

1. Routine Maintenance

- Daily Inspections: Check for leaks, wear, and damage to critical components.

- Lubrication: Ensure all moving parts are properly lubricated according to the manufacturer’s guidelines.

- Replace Worn Parts: Identify and replace worn or damaged components promptly to prevent further issues.

2. Troubleshooting Common Issues

- Loss of Rotation: Check for power supply issues or mechanical failures in the drive system.

- Poor Penetration Rates: Assess weight on bit, rotation speed, and drill bit condition.

- Excessive Vibration: Inspect for misalignment, unbalanced loads, or wear in the drill string.

Conclusion

Mastering rotary drilling rigs requires a blend of technical knowledge, operational skills, and safety awareness. By following the tips and techniques outlined in this guide, you can enhance your proficiency and ensure efficient, safe drilling operations. Remember, continuous learning and adaptation are key to excelling in this vital field.

For more details on specific adjustments and maintenance practices, consult another article or contact a qualified technician.

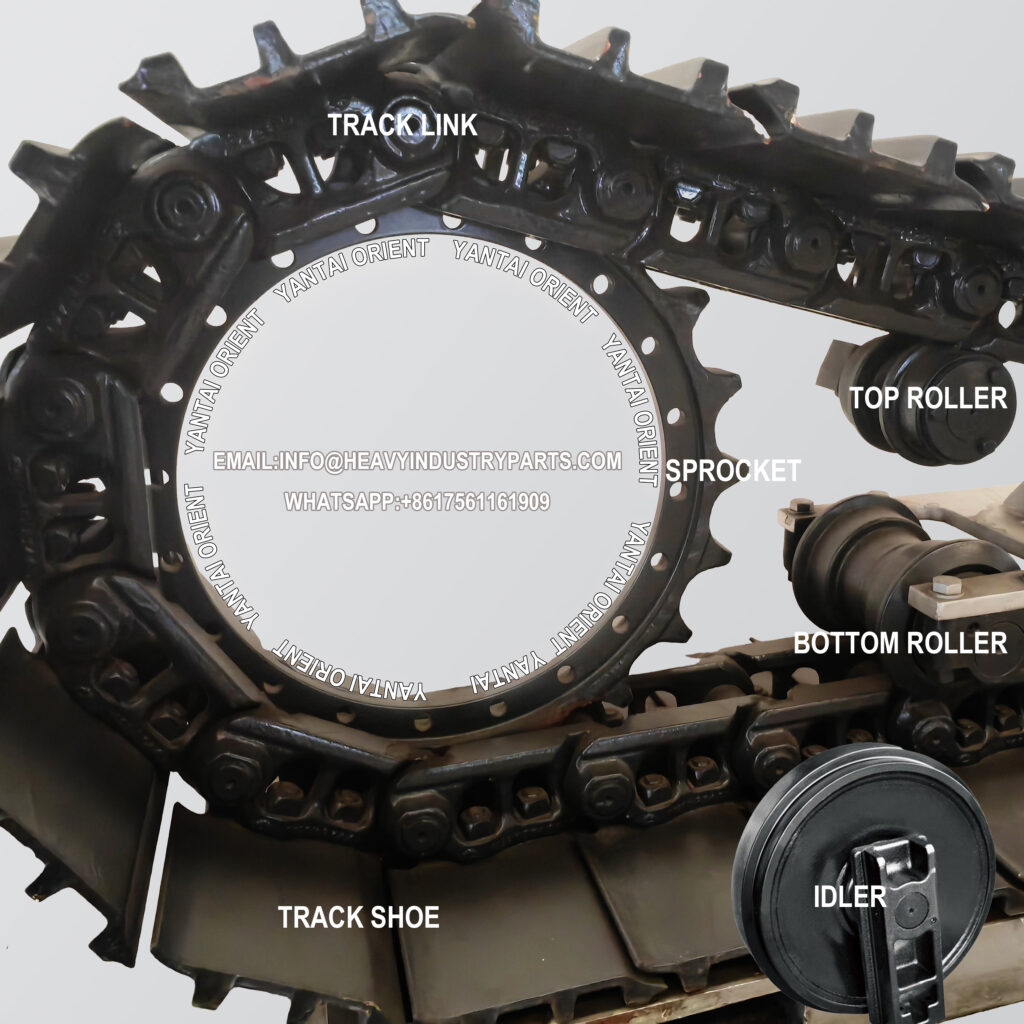

If you have any inquiries about Drilling Rig Undercarriage Parts, such as track shoes, track chain assembly, track roller, carrier roller, sprocket, and idler. Please feel free to contact us.

Our Alibaba: https://ytrtzg.en.alibaba.com/?spm=a2700.shop_cp.88.12