New Year, New Momentum: Committed to Excellence in Undercarriage Parts

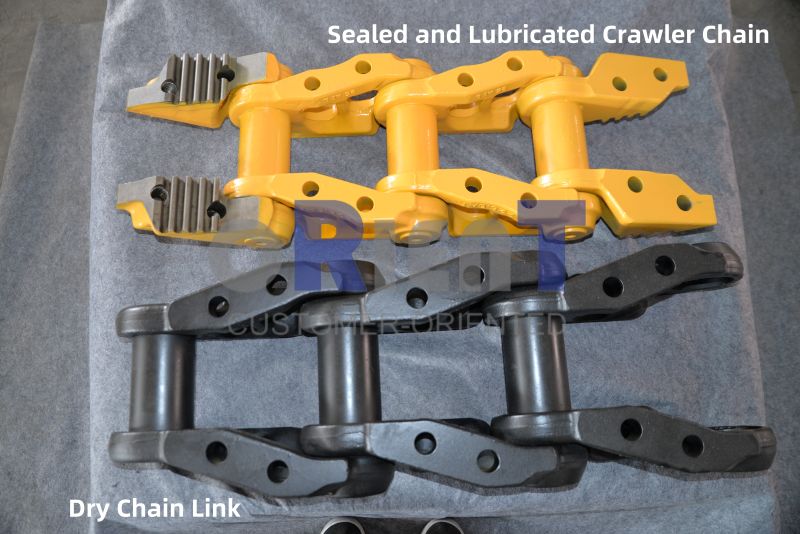

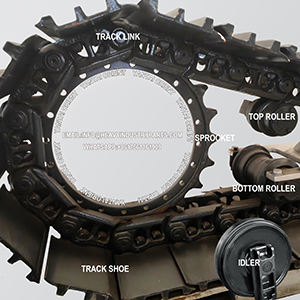

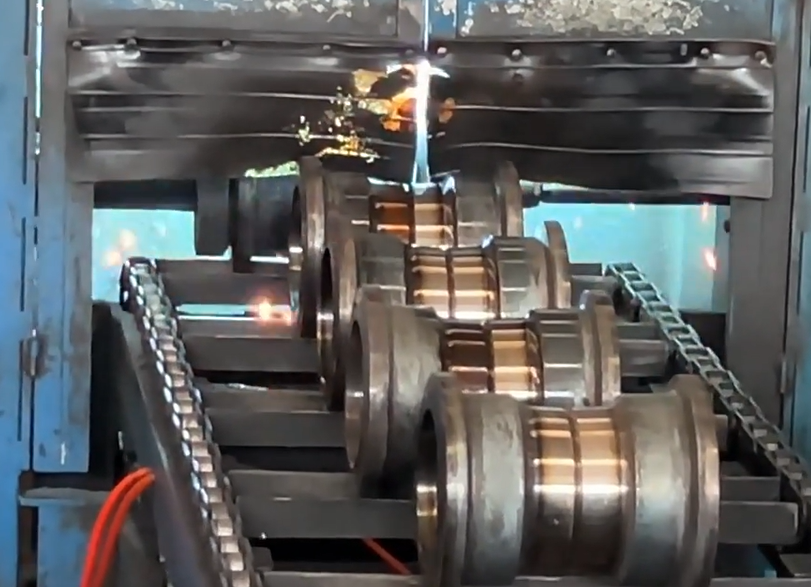

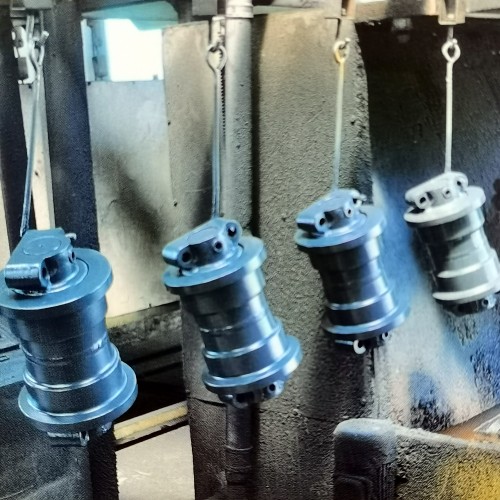

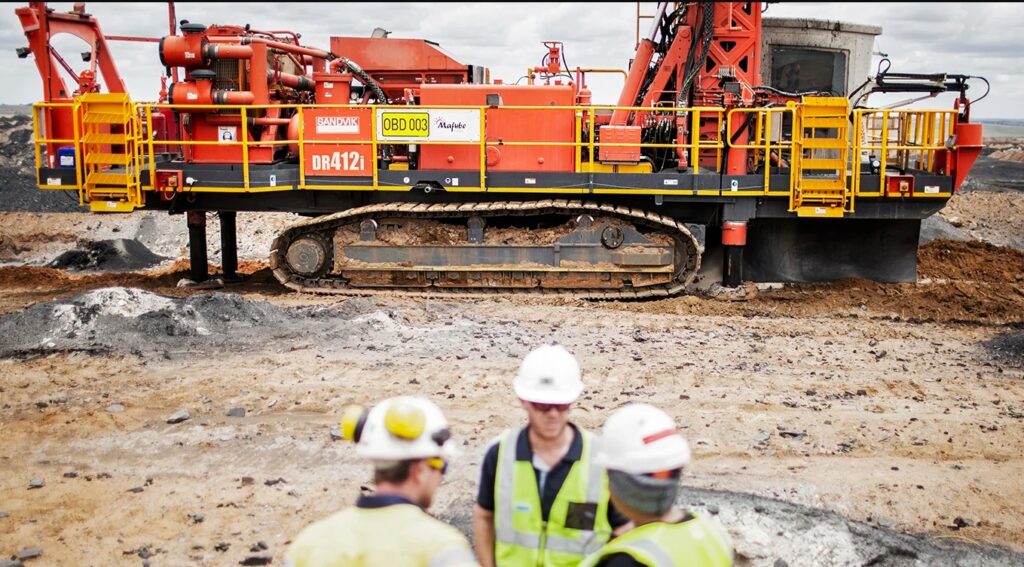

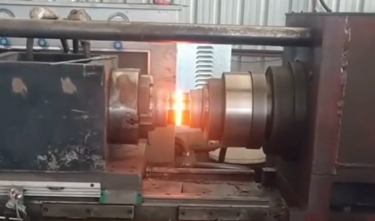

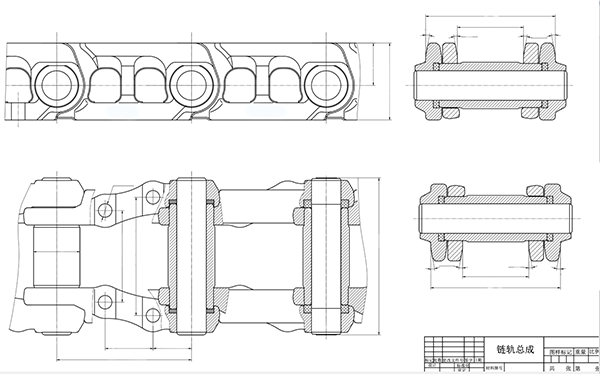

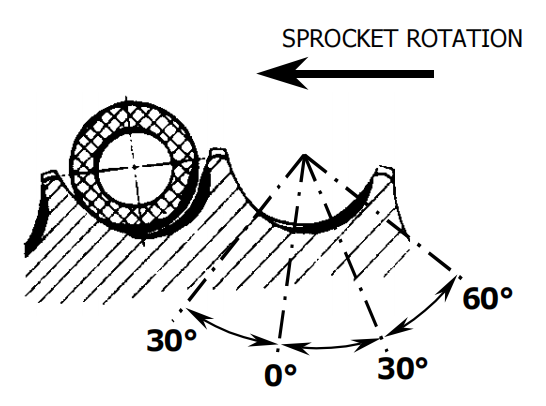

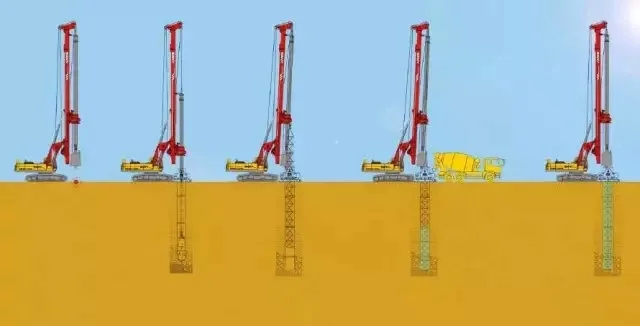

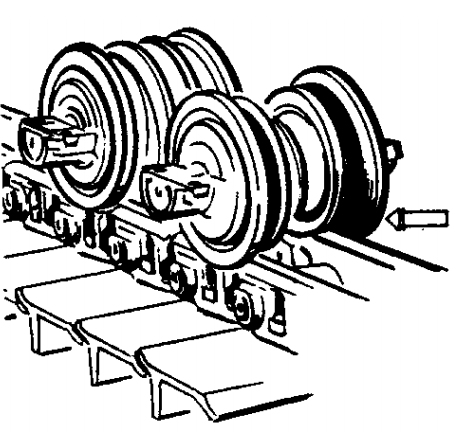

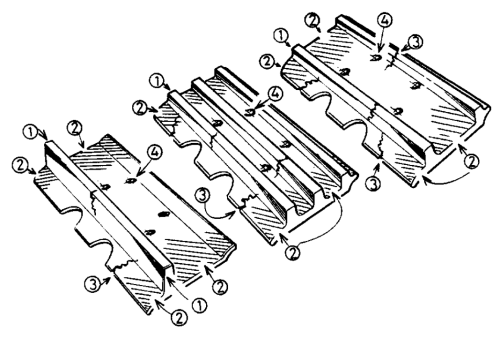

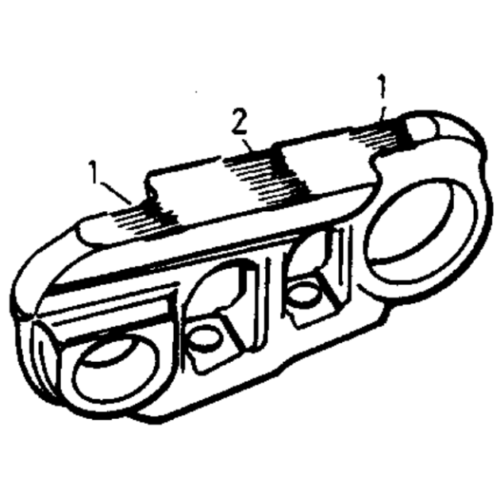

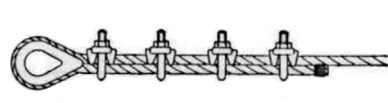

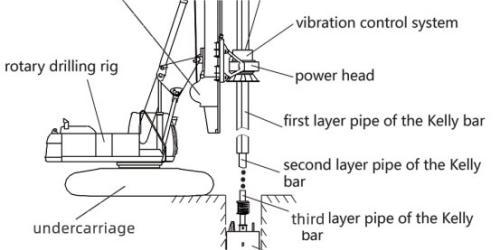

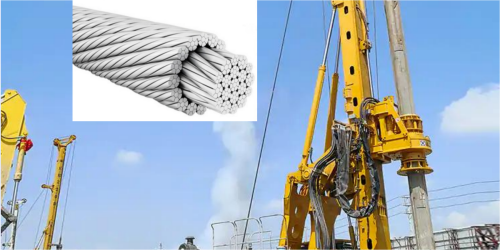

As the New Year begins, we warmly extend our sincere greetings to all our valued customers, partners, and employees for their continued support and trust. As a professional supplier of undercarriage components, we specialize in track systems and related parts, including drive wheels, idlers, carrier rollers, track rollers, and track shoes, widely used in rotary […]

New Year, New Momentum: Committed to Excellence in Undercarriage Parts Read More »