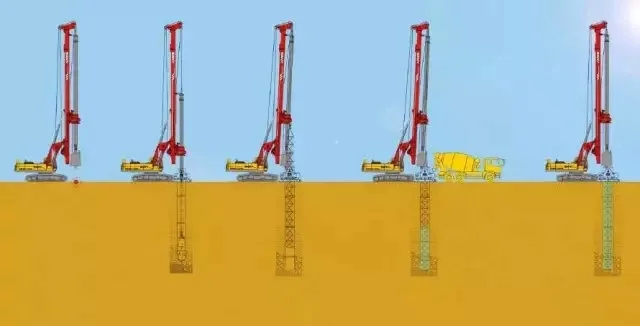

The Application of Rotary Drilling Rig in Municipal Engineering

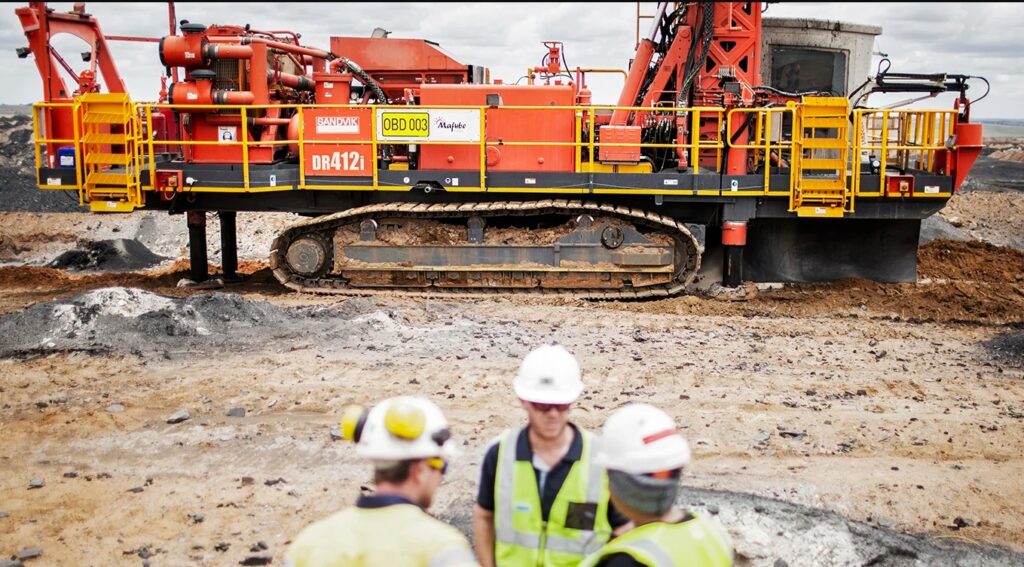

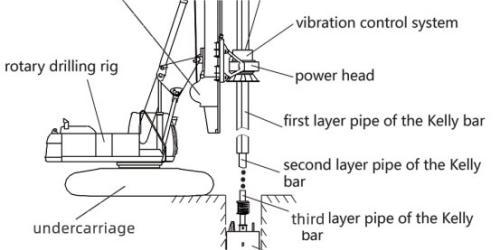

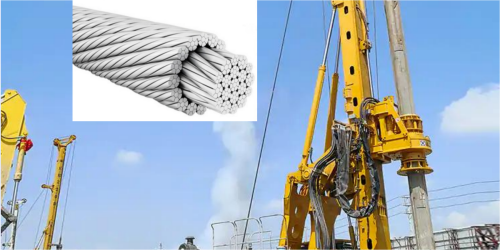

With continuous global urban expansion, municipal infrastructure construction faces higher technical and operational requirements. Project owners increasingly expect faster construction cycles, precise borehole control, and reduced environmental impact. The rotary drilling rig has become a reliable solution for modern municipal pile foundation construction worldwide. In urban bridge foundations, this rotary drilling rig delivers consistent torque […]

The Application of Rotary Drilling Rig in Municipal Engineering Read More »