There are many energy-saving tips for rotary drilling rigs, and proper drilling rig maintenance can actually achieve the goal of fuel efficiency. How to maintain to achieve fuel efficiency?

1. Keep the Air Filter Clean

If the air filter is too dirty, it will cause high air flow resistance, incomplete combustion of the mixture, and a decrease in engine power.

To maintain the air filter, the following points should be achieved:

- Check and clean the air filter element every 100 hours.

- Replace the air filter element every 500 hours.

- During maintenance, the filter element should not be cleaned by impact or knocking.

- Compressed air, pressure water, or detergent can be used for cleaning.

- Before installing the filter element into the filter housing, ensure that the cleaned filter element is completely dry.

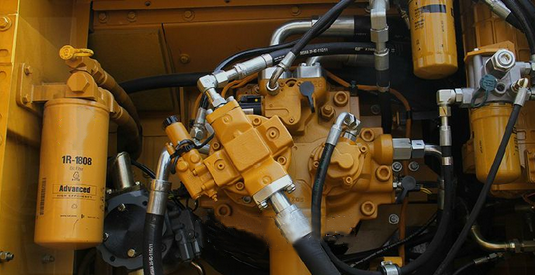

2. Regular Drilling Rig Maintenance of Fuel System

If the fuel filtration effect is poor, impurities in diesel can enter the fuel injection pump, which can accelerate the wear of precision components, resulting in a decrease in engine power and an increase in fuel consumption.

If moisture and gum in the fuel enter the cylinder, it will cause poor combustion of the combustible mixture, leading to a decrease in engine power and an increase in fuel consumption.

Therefore, it is necessary to regularly replace the fuel coarse and fine filter elements, and regularly check whether the fuel pump and fuel injector are leaking or damaged. If there is leakage or damage to the fuel pump and nozzle, it should be repaired in a timely manner. In addition, choose high-quality fuel.

3. Regularly Change the Engine Oil

Failure to change the oil according to the prescribed time or improper selection of oil can exacerbate the wear of engine components. This has a negative impact on the performance and lifespan of the engine, leading to an increase in engine fuel consumption. Therefore, it is necessary to strictly follow the instructions for use and choose the same series, grade, and viscosity of engine oil. And regularly replace the engine oil according to the instructions.

4. Other Component Maintenance of Rotary Drilling Rig

Adjust the tension of the track shoe assembly appropriately. Timely clean the soil adhering to the undercarriage. This can reduce walking resistance and lower walking fuel consumption.

In addition, try to keep the hydraulic oil radiator and water radiator clean as much as possible. Maintain the temperature of hydraulic oil and coolant within a reasonable range. This is beneficial for improving homework efficiency and reducing fuel consumption.

Our Alibaba: https://ytrtzg.en.alibaba.com/?spm=a2700.shop_cp.88.12