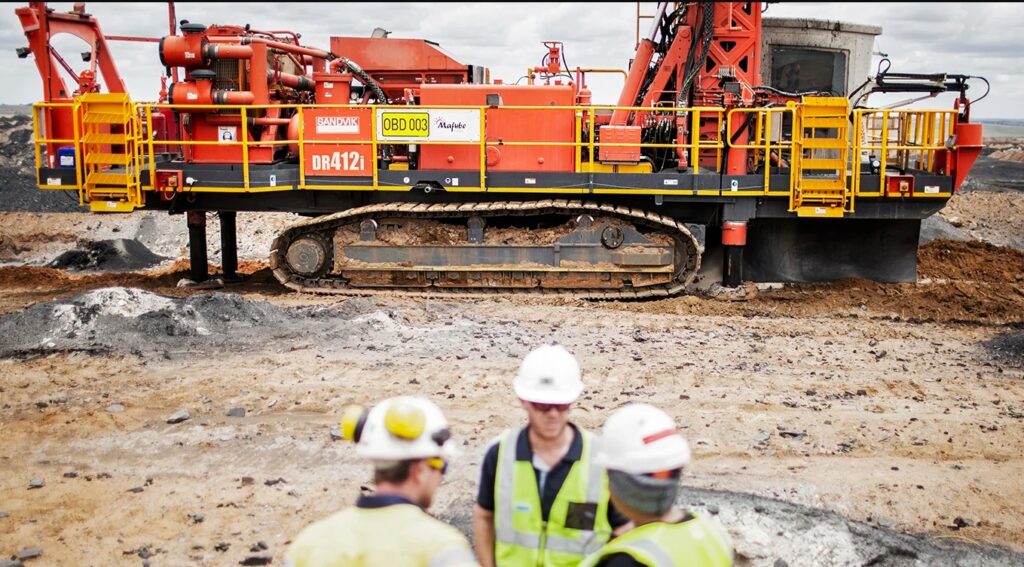

DR412i blasthole drill is designed to deliver dependable penetration and greater return on investment for rotary and DTH holes.

Sandvik recently delivered a fifth DR412i rotary blasthole drilling rig to Glencore Australia’s Hail Creek coal mine, with another DR412i scheduled for future delivery which would bring the fleet size to six. Sandvik stated: “The DR412i blasthole drill is designed to deliver dependable penetration and greater return on investment. And we are excited to see the results this fleet of DR412i’s provides Glencore.”

About DR412i

The 18 m mast on this rig model delivers a total depth capacity of 33.1 m, removing the need to add pipe, which improves productivity and reduces costs. It is standard equipped for rotary with optional down-the-hole (DTH) hammer drilling power.

A single centralized service center shortens the time for fluid fills, improves utilization, and reduces the risk of fluid spills and harmful environmental impact. The Sandvik Intelligent Control System Architecture (SICA) gives the operator real-time feedback about DR412i’s performance and health, along with tools for drill planning, reporting, and analysis, improving availability and productivity. It uses a CAN bus-controlled hydraulic system to monitor the machine, allowing for timely preventative maintenance and delivering higher availability.

It can drill holes of 203-311 mm with a single pass hole depth of up to 17.8 m. Pipes can be handled from within the cab using the Sandvik carousel and breakout system, with optional hands-free bits changing capability. A new-generation ergonomically-designed cab includes armrest controls, touchscreens, angled windows to reduce glare and a safari-style roof to keep the cab cooler. Wider, 360-degree walkways enable superior drill access for routine maintenance. An optional hydraulic main-access stairway can be mounted to provide a parallel step onto and off of the drill.

Advanced compressor management reduces the compressor load allowing the operator to manage air volumes and pressures to maximize efficiency and reduce fuel burn reducing CO₂ footprint and extending engine and compressor life.

The article is reproduced from there. More undercarriage parts of Sandvik you can find it in the products.