XCMG XR160 Drive Wheel for BORING MACHINE

Product Description:

Technology:Casting

Feature:Heat treated Sprocket

Material:40Mn2;35SiMn;ZGSCSiMn2H

Warranty:2500 Working Hours / One Year

Certification:ISO9001

Color:Black / Customer Requirement

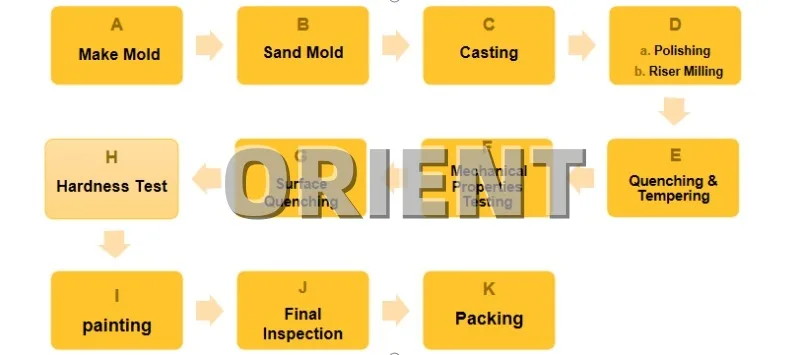

Production Process:

High quality raw materials:

Yantai Orient cooperates with domestic first-class steel factories and uses high-quality raw materials.

This improves the strength and durability of the sprocket drive, making it better able to withstand heavy loads and long-term use, and extending its service life.

Drilling rig undercarriage maintenance:

1. When stopping work in a short period of time, a small amount of compressed air should be given to prevent sediment from invading the inside of the drilling rig impactor. If the drilling rig operation is stopped for a long time, the impactor should be raised 1-2 meters away from the bottom of the hole and fixed.

2. Always check the lubricating oil condition of the wind motor.

3. When the working surface is immersed in water, use a large-diameter drill bit when opening the hole and insert the drill pipe so that the drill pipe is 1-2 meters above the water surface to prevent mud and rock slag from falling into the hole.

4. No reversal is allowed during drilling operations to prevent the drill pipe from falling into the hole;

5. Always check the water and gas pipelines of the crawler drilling rig to see if the bolts and nuts of each accessory are tight.

Video Show:

Reviews

There are no reviews yet.