IMT AF270 Idler for Piling Rig

Why choose Our IMT AF270 Idler for Piling Rig?

- Use high level raw material 32MnB for the roller body, ensure the strong toughness of the idler wheel. Each bach of raw material will be inspected to ensure the qualification from the source.

- The shaft we produce has smooth appearance.

- All the size of idler wheel is standard and the deviation is within the allowable range.

- Oil passage is smooth. Each idler wheel will make an inspection of oil leakage.

- We use good floating oil seal to seal the oil. There will be no oil leakage after long-term use.

Production process of our IMT AF270 Idler Wheel:

Make mold → Sand mold → Casting → Polishing → Quenching & tempering → Surface hardening → Painting → Packing

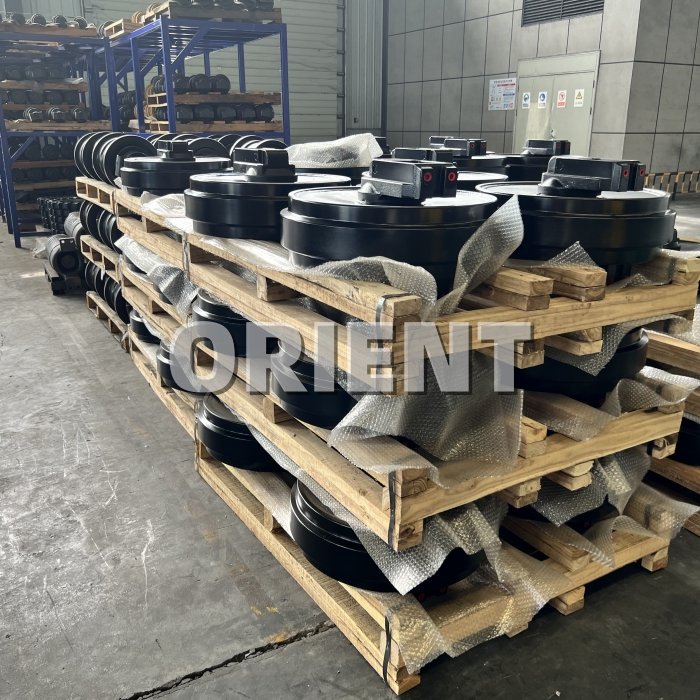

Package:

Related undercarriage parts:

TRACK SHOE/TRACK CHAIN/TRACK ROLLER/TOP ROLLER/DRIVE SPROCKET

Why choose us for rotary piling rig undercarriage parts?

- Have been in the industry of undercarriage parts for more than 20 years. Accumulated rich experience in this industry.

- Own advanced casting, forging and heat treatment equipment and clean and environmental workshop.

- Fully staffed. Engineer team, sales team, operation team, warehouse staff. All staff are professional and perform their duties.

- Rich experience of exporting to 30+ countries about 1000+ customers.

- Our undercarriage parts are suitable for many famous brands and models. Such as Bauer, Soilmec, IMT, CMV, Liebherr, Casagrande, Sandvik, Juttan, Sany, XCMG, Zoomlion, Sunward, Jintai, etc.

- Each our product can meet the international standard.

- We have certifications like ISO9001 and SGS. If having special requirements, we will try our best to meet your satisfaction.

- Package of us can meet the export standard.

- Fast delivery. Usually 7-25 days for production. For many common parts, we usually stock some for emergency orders.

Reviews

There are no reviews yet.