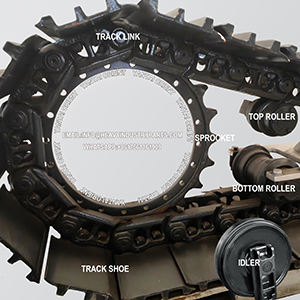

Main chassis components

PRODUCT INFORMATION

| Product Information | KOBELCO P&H330 Crawler Crane Machine undercarriage parts |

| Material | 40Mn2 |

| Finish | Smooth |

| Colors | Black / Customer Requirement |

| Technique | Forging → Heat treatment (quenching and tempering) → Welding |

| Warranty time | 1 years/2500 working days |

| Certification | ISO9001 |

| FOB Price | Negotiate |

| MOQ | 1 PCs |

| Delivery Time | 15-25days after payment |

| Package | Pallet / Plywood Case |

| Payment Term | TT;LC;Negotiate |

| Applicable industries | Shop construction material, Shop machinery repair, Manufacturing plant, Retail, Construction work, Energy and Mining, Construction work |

| Location Exposure | Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, United Arab Emirates, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Nigeria, Malaysia, Spain |

| Business Scope | Drilling rig, Crawler Crane,Bulldozer, Excavator |

TheKOBELCO P&H330 crawler crane undercarriage components we offer include but are not limited to:

Track Chain Assy: Precision machined to ensure efficient and smooth travel under heavy loads.

Sprockets: high-strength material with strong load-bearing capacity ensures efficient driving of the track system.

Idlers: Precision machined to ensure track tensioning and guide the tracks to run smoothly.

Track Rollers: Highly wear-resistant, providing excellent smoothness and load-carrying capacity, and reducing component wear.

Product Features

Our undercarriage parts are made of high-strength materials, precision machined and rigorously tested, with the following advantages:

- High quality raw material. We use 32MnB, 40Mn2 and so on material to control the high quality from the source. Before production, our engineer will analyze the chemical components of the raw material.

- Good appearance. Due to advanced casting and welding technique, each idler of us has good appearance.

- Strong hardness. Through heat treatment, whole quenching then surface hardening, our idler has strong hardness and could withstand high impact.

- High wear-resistance. After tempering, the quenching stress is eliminated, increase the toughness of the idler , make it have high wear-resistance.

MAIN PRODUCTS – TRACK SHOE, TRACK CHAIN, TRACK ROLLER, TOP ROLLER, SPROCKET, IDLER

AVAILABLE BRANDS – BAUER, SOILMEC, CASAGRANDE, IMT, CMV, LIEBHERR, SANDVIK, ATLAS COPCO, JUNTTAN, SANY, ZOOMLION, XCMG, SUNWARD, JINTAI, ETC.

| Suitable Brands & Models | |

| Undercarriage Parts for Rotary Drilling Rig | |

| Brands | Models |

| Bauer | BG12, BG15, BG18, BG20, BG20H, BG22, BG22H, BG24, BG24H, BG25, BG25C, BG25H, BG26, BG28, BG28V, BG30, BG33H, BG34, BG36, BG36H, BG39, BG40, BG45, BG50, GB34, GB50, MBG12, MBG24, RTG RG22S, RTG RM20, UW110, etc. |

| Soilmec | SR13, SR15, SR20, SR30, SR40, SR60, SR65, SR70, SR75, SR80, SR80C, SR90, SR95, SR100, R16, R208, R208 (HD), R208, R312, R312/200, R312HD, R415, R515, R618, R620, R622, R622HD, R724, R725, R825, R930, etc. |

| Casagrande | B80, B125, B170, B180, B180HD, B250, B250XP, B300, B400, C6XP, C7XP, C8, C25, C30, C50, C60, C60HD, C90, C250, C400, C600, C600ZN, etc. |

| IMT | AF10, AF12, AF18, AF35, AF180, AF190E, AF190F, AF200, AF215, AF250E, AF250F, AF270, AF270E, AF280, AF290, AF300, AF300E, AF350D, A215, etc. |

| CMV | TH15-50, TH18-65, TH20, TH32, MK1200M, etc. |

| MAIT | HR100, HR110, HR130, HR150, HR180, HR260, HR360, MC180 etc. |

| LIEBHERR | LB24, LB28, LB36, LHR100, LRB255, LRB355, etc. |

| Atlas Copco | D45, D50, D55, D60, D65, DM30, DM45, DM45E, DM45HP, DM50,DM65 DM50LP, DM75, DMH, DMH/XL2600, DML, DML-HP, DML-LP, DMM2, DMM3, ECM590, EPIROC D50, EPIROC D55, FLEXI ROC D55, FLEXI ROC D60, FLEXI ROC D65, PV271, PV271D, PV275, PV275E, PV351, PV351D, PV351E, PVE5021, ROCL6, ROCL6-44, ROCL6-5M, AMM2, SmartRoc D65, etc. |

| Sandvik | AM50, DX700,DX800, DP1500, Leopard DI650I, etc. |

| SANY | SR150, SR155, SR205, SR220, SR235, SR265, SR280, SR280C, SR285, SR285R, SR360, SR365, SR365RC10, SR400R, SR405R, SR415, SR485, Leopard DI650I, etc. |

| XCMG | XR130, XR150, XR160, XR180, XR220, XR240, XR280, XR360, XR400, XR460, XR550, XR800, XRS1050, XR3200, SR280C, etc. |

| ZOOMLION | ZR125C, ZR160C, ZR240C, ZE280C, ZR360C, ZR ZR160L, ZR160A-1, ZR220C, ZR280C, ZR280C-2, ZR300L, ZR360L, ZR380L, ZR400L, ZR450L, ZR500L, ZR650L, ZR140L, ZR550L, ZR220A, etc. |

| SUNWARD | SWDM40, SWDM60, SWDM80, SWDM130, SWDM160, SWDM160H2, SWDM200H, SWDM240, SWDM240H, SWDM240-2, SWDM260, SWDM280, SWDM300, SWDM300H, SWDM300H-2, SWDM360, SWDM360A, SWDM360H3, SWDM420, SWDM420V, SWDM450V, SWDM480, SWDM500, SWDM500V, SWDM550H2, SWDM600, SWDM800, SWDM1000, SWDM1280,SA175 etc. |

| FURUKAWA | HCR1200, HCR1200 DS III, HCR1201 DS III, HCR1202 DS III, HCR1203 DS III, HCR1800, HCR900-XSII, HCR901-XSII, HCR902-XSII, HCR903-XSII,HCR904-XSII, ,DCR20, ,DCR21, DCR22, DCR23, DCR24 |

| JINTAI | SD12, SD20, SD22, SD28, SD30, SD32, SH25CW, SH36E, SH-36W, SH46AW, etc. |

| Hyundai | Everdigm D700, Everdigm D800,etc. |

| JUNTTAN | PM25, PM26, etc. |

| SENNEBOGEN | SR40T, 860M, etc. |

| DELMAG | RH18W, etc. |

| Epiroc | DML 1, etc. |

| KLEMM | 806-4, etc. |

| Solitek | S-60, etc. |

| TESCAR | CF06, etc. |

| Comacchio | MC 800-S, etc. |

| Can’t find the model you need? Provide parts manual we can customize for you! | |

Reviews

There are no reviews yet.