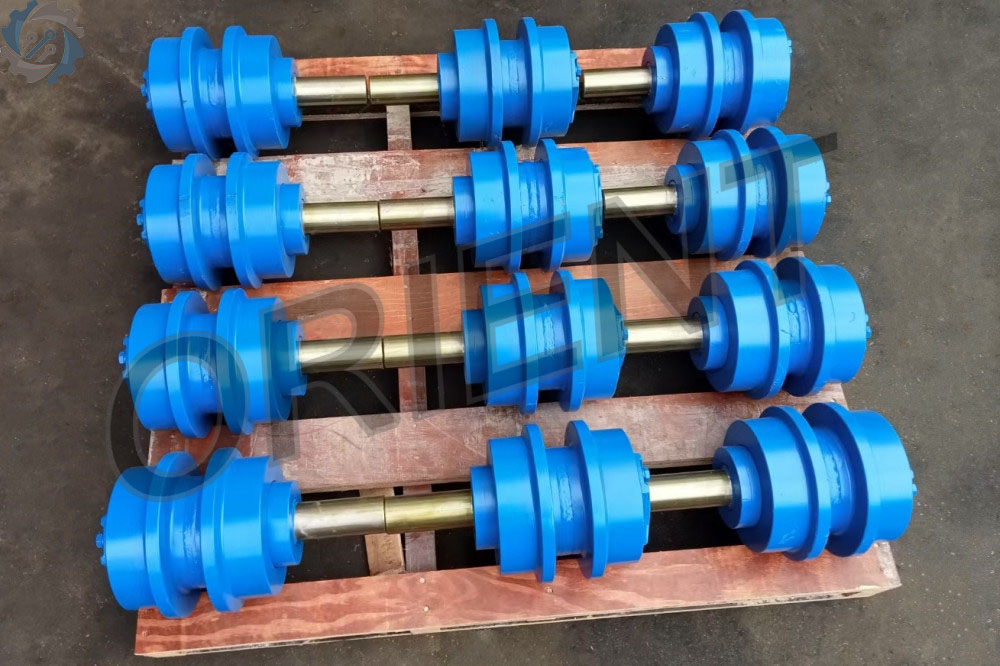

Bauer BG20 Carrier Roller Product Details

| Product Name | Bauer BG20 Carrier roller Top Roller |

| Material | 40Mn2 |

| Colors | Black / Customer Requirement |

| Technique | Forging → Heat treatment (quenching and tempering) → Welding→Heat Treatment→ Surface Hardness |

| Warranty time | 1 years/2500 working days |

| Certification | ISO9001 |

| Trade Terms | EXW, FOB, FCA, CFR, CIF, DAP, DDU |

| MOQ | 1 PCs |

| Delivery Time | 15-25days after payment |

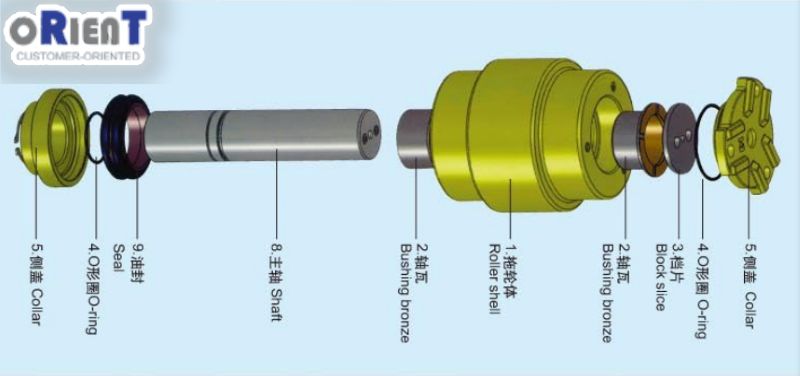

Bauer BG20 Structural

Production Process of Bauer BG20

- Material Selection

- Raw Materials: High-quality alloy steel or carbon steel is typically used due to its strength, durability, and resistance to wear and tear.

- Machining

- Cutting: The raw material is cut into the desired size and shape using cutting tools such as saws or plasma cutters.

- Turning: The cut pieces are then turned on a lathe to achieve the precise dimensions and smooth surface finish required for the upper rollers.

- Drilling and Boring: Holes are drilled and bored to accommodate bearings, shafts, and other components.

- Milling: Additional machining processes such as milling may be performed to create specific features or contours on the upper rollers.

- Heat Treatment

- Hardening: The machined upper rollers undergo heat treatment processes such as quenching and tempering to enhance their hardness and durability.

- Surface Hardening: Techniques like induction hardening or carburizing may be used to harden the surface of the upper rollers while maintaining a tough core.、

- Grinding and Finishing

- Grinding: The upper rollers are ground to achieve precise dimensions and a smooth surface finish. This step ensures proper fit and function within the piling rig.

- Polishing: Additional polishing may be done to reduce friction and wear during operation.

- Assembly

- Bearing Installation: Bearings are installed into the machined holes to facilitate smooth rotation.

- Sealing: Seals are added to protect the bearings from dirt, debris, and moisture, extending the lifespan of the upper rollers.

- Lubrication: Proper lubrication is applied to ensure smooth operation and reduce wear.

- Quality Control

- Inspection: Each upper roller is inspected for dimensional accuracy, surface finish, and overall quality.

- Testing: Functional testing is conducted to ensure the upper rollers operate smoothly and can withstand the expected loads and stresses.

Reviews

There are no reviews yet.