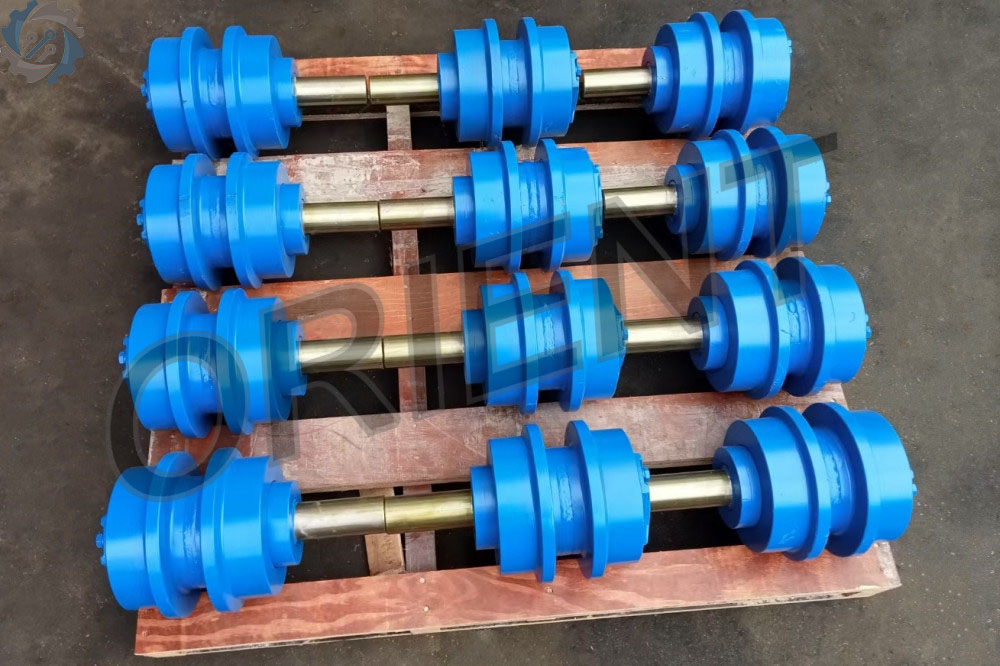

Bauer BG22H Carrier Rollers Product Details

| Product Name | Bauer BG22H Carrier Rollers/ Top Rollers / Upper Rollers |

| Material | 40Mn2 |

| Colors | Black / Customer Requirement |

| Technique | Forging → Heat treatment (quenching and tempering) → Welding→Heat Treatment→ Surface Hardness |

| Warranty time | 1 years/2500 working days |

| Certification | ISO9001 |

| Trade Terms | EXW, FOB, FCA, CFR, CIF, DAP, DDU |

| MOQ | 1 PCs |

| Delivery Time | 15-25days after payment |

Bauer BG22H Carrier Roller Structural

Bauer Undercarriage Parts Available Models

BG12, BG15, BG18, BG20, BG20H, BG22, BG22H, BG24, BG24H, BG25, BG25C, BG25H, BG26, BG28, BG28V, BG30, BG33H, BG34, BG36, BG36H, BG39, BG40, BG45, BG46, BG50, GB34, GB50, MBG12, MBG24, RTG RG22S, RTG RM20, UW110, etc.

Production Process of Bauer BG22H Carrier Rollers

Material Selection

- Use high-quality alloy steel or carbon steel for strength, durability, and wear resistance.

Machining

Cutting: Cut the raw material into the required size and shape with saws or plasma cutters.

Turning: Turn the cut pieces on a lathe to reach precise dimensions and a smooth surface finish.

Drilling and Boring: Drill and bore holes for bearings, shafts, and other components.

Milling: Perform milling to create specific features or contours on the Bauer BG22H upper rollers.

Heat Treatment

Hardening: Quench and temper the rollers to increase hardness and durability.

Surface Hardening: Apply induction hardening or carburizing to harden the surface while keeping a tough core.

Grinding and Finishing

Grinding: Grind the carrier rollers to achieve exact dimensions and a smooth finish, ensuring proper fit and function.

Polishing: Further polish the surface to reduce friction and wear during operation.

Assembly

- Bearing Installation: Insert bearings into the holes to ensure smooth rotation.

- Sealing: Add the seals to block dirt, debris, and moisture, extending the parts’ service life.

- Lubrication: Apply lubricant to support smooth operation and minimize wear.

Shipping Methods: Express, Air, Rail, Sea

Reviews

There are no reviews yet.