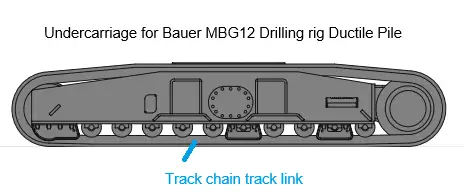

Details of the Bauer MBG12 track chain

| Goods description | Track chain, track link |

| Suitable model | Bauer MBG12 |

| Machine type | Drilling rig, Ductile Pile |

| Material | 35MnB |

| Colour | Black, blue, or as required |

| Condition | 100% brand new |

| Technique | Forging |

| Heat treatment | Quenching and tempering, surface hardening |

| Packing | Plywood pallet, plywood case, iron pallet |

| Loading port | Yantai, Qingdao, Shanghai, Guangzhou, Yiwu, etc. |

| Trade term | EXW, FOB, CFR, CIF, DDU, DAP |

| Warranty time | 1 year |

| MOQ | 1 piece |

Function of the Bauer MBG12 track chain

- Together with the track shoe, track bolt, and track nut, assemble into a track group assy, provide driving force and support, enable the rig machine to travel and operate on various complex terrains.

- It transmits the engine power to the ground by connecting the sprocket, allowing the rig machine to move forward, backward, and turn.

Production process

Cutting → Forging → Rough machining → Quenching and tempering → Medium frequency →Tempering → Finishing → Assembly → Painting

Shipment photos

Related products

- track shoe/track pad for Bauer MBG12

- track roller/bottom roller for Bauer MBG12

- carrier roller/top roller for Bauer MBG12

- sprocket/drive wheel for Bauer MBG12

- idler/guide wheel for Bauer MBG12

Principles of track chain adjustment

- The track chain needs to be adjusted slightly tighter to avoid the track from being too loose and colliding with the lower frame, causing wear, when the drilling rig is working on a hard surface.

- It is best to adjust the track looser when the drilling rig is working on a soft surface, because the soil is easy to adhere to the chain links and tracks, which can reduce the abnormal pressure of the soil on the chain links.

- When adjusting the track tightness, do not adjust it too loose or too tight. It must be moderate. If the track is too tight, it will affect the walking speed and walking power, and increase the wear between the various components. If it is adjusted too loosely, the loose track will cause great wear on the drive wheel and the drag chain wheel.

Other brands

| Undercarriage Parts for Rotary Drilling Rig | |

| Brands | Models |

| Bauer | BG12, BG18, BG20, BG20H, BG22H, BG24, BG24H, BG25, BG25C, BG25H, BG26, BG28, BG28V, BG30, BG33H, BG34, BG36, BG36H, BG39, BG40, GB34, GB50, MBG12, MBG24, RTG RG 22S, RTG RM20, etc. |

| Soilmec | SR30, SR40, SR60, SR65, SR70, SR75, SR80, SR80C, SR90, SR95, SR100, R16, R208, R312, R415, R515, R618, R620, R622, R622HD, R724, R725, R930, etc. |

| Casagrande | B125, B180, B180HD, B250, B250XP, B300, B400, C6XP, C7XP, C25, C30, C50, C60, C60HD, C90, C250, C400, C600, C600ZN, etc. |

| IMT | AF10, AF12, AF18, AF35, AF180, AF190, AF200, AF215, AF250E, AF250F, AF270, AF270E, AF280, AF290, AF300, AF300E, AF350D, etc. |

| CMV | TH15-50, TH18-65, TH20, TH32, MK1200M, etc. |

| Mait | HR100, HR180, HR260, HR360, MC180, etc. |

| LIEBHERR | LB24, LB28, LB36, LHR100, LRB255, LRB355, etc. |

| Atlas Copco | D45, D50, D55, D60, D65, DM30, DM45, DM50, DM65, DM75, DML, AMM2, DMM2, DMM3, PV271, PV275, PV351, Flexi roc D60, Flexi roc D65, ROCL6, ROCL6-44, etc. |

| DELMAG | RH18W, etc. |

| JUNTTAN | PM25, PM26, etc. |

| Sandvik | AM50, DX800, DP1500, etc. |

| SANY | SR150, SR155, SR205, SR220, SR235, SR265, SR280, SR285, SR360, SR365, SR365RC10, SR405, SR415, SR485, etc. |

| XCMG | XR130, XR150, XR160, XR180, XR220, XR240, XR280, XR360, XR400, XR460, XR550, XR800, XRS1050, etc. |

| ZOOMLION | ZR125C, ZR140L, ZR160A-1, ZR160C, ZR160L, ZR220A, ZR220C, ZR240C, ZR280C, ZR280C-2, ZR300L, ZR360L, ZR380L, ZR400L, ZR450L, ZR500L, ZR550L, ZR650L, etc. |

| SUNWARD | SWDM40, SWDM60, SWDM80, SWDM130, SWDM160, SWDM160H2, SWDM200H, SWDM240, SWDM240H, SWDM240-2, SWDM260, SWDM280, SWDM300, SWDM300H, SWDM300H-2, SWDM360, SWDM360A, SWDM360H3, SWDM420, SWDM420V, SWDM450V, SWDM480, SWDM500, SWDM500V, SWDM550H2, SWDM600, SWDM800, SWDM1000, SWDM1280, etc. |

| JINTAI | SD12, SD20, SD22, SD28, SD30, SD32, SH25CW, SH46AW, etc. |

| Can’t find the model you need? Provide the parts manual we can customize for you! | |

FAQ

How to properly maintain the drilling rig track group?

How to Reduce Wear of the Track Link?

What are the causes of drilling rig track shoe damage?

Reviews

There are no reviews yet.