Details of the Bauer GB50 idler

| Goods description | Idler, guide wheel, sloth |

| Suitable model | Bauer GB50 |

| Machine type | Drilling rig, Hydraulic Grab Carrier |

| Material | 32MnB |

| Colour | Black, blue, or as required |

| Technique | Casting |

| Heat treatment | Quenching and tempering, surface hardening |

| Condition | 100% brand new |

| Packing | Plywood pallet or wooden pallet |

| Loading port | Yantai, Qingdao, Shanghai, Guangzhou, Yiwu, etc. |

| Trade term | EXW, FOB, CFR, CIF, DDU, DAP |

| Warranty time | 1 year |

| MOQ | 1 piece |

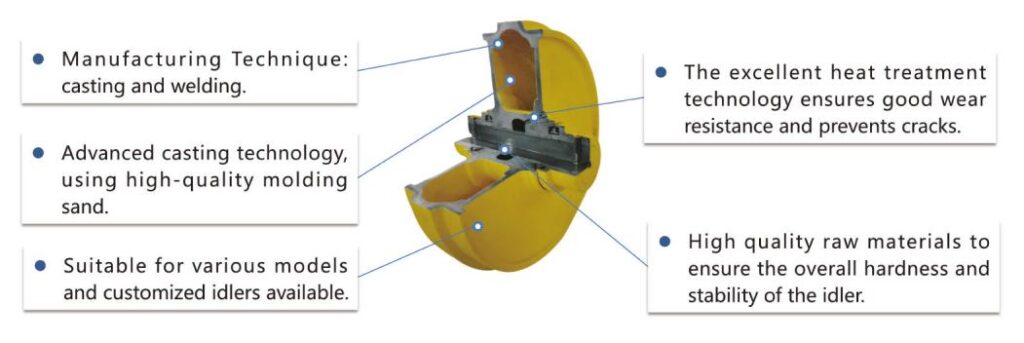

Advantages of our Bauer GB50 idler

Shipment photos

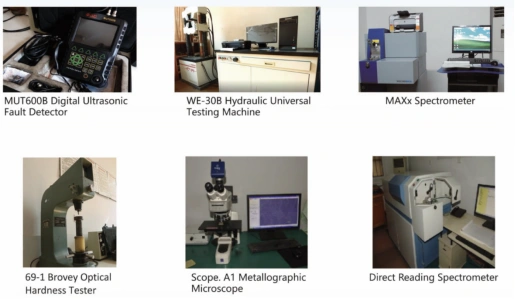

Strict quality control

Maintenance of the guide wheel

- Keep the guide wheel in position. Make sure the guide wheel is kept in front of the X-frame when the excavator is working and traveling.

- Check the tension spring. Ensure that it functions properly and can effectively absorb shock and reduce wear. If the tension spring is damaged, replace it in time.

- Avoid mud and water immersion. Avoid the guide wheel from being immersed in mud and water for a long time, especially in winter, so as to prevent water from entering the floating seal and freezing, causing seal damage and oil leakage.

- Regularly clean the mud and gravel around the guide wheel to prevent excessive accumulation from affecting its rotation.

- Professional maintenance. If serious problems, such as bearing damage, seal failure, etc., professionals should be asked to inspect or replace it in time.

Available brands and models

| Undercarriage Parts for Rotary Drilling Rig | |

| Brands | Models |

| Bauer | BG12, BG18, BG20, BG20H, BG22H, BG24, BG24H, BG25, BG25C, BG25H, BG26, BG28, BG28V, BG30, BG33H, BG34, BG36, BG36H, BG39, BG40, GB34, GB50, MBG12, MBG24, RTG RG 22S, RTG RM20, etc. |

| Soilmec | SR30, SR40, SR60, SR65, SR70, SR75, SR80, SR80C, SR90, SR95, SR100, R16, R208, R312, R415, R515, R618, R620, R622, R622HD, R724, R725, R930, etc. |

| Casagrande | B125, B180, B180HD, B250, B250XP, B300, B400, C6XP, C7XP, C25, C30, C50, C60, C60HD, C90, C250, C400, C600, C600ZN, etc. |

| IMT | AF10, AF12, AF18, AF35, AF180, AF190, AF200, AF215, AF250E, AF250F, AF270, AF270E, AF280, AF290, AF300, AF300E, AF350D, etc. |

| CMV | TH15-50, TH18-65, TH20, TH32, MK1200M, etc. |

| Mait | HR100, HR180, HR260, HR360, MC180, etc. |

| LIEBHERR | LB24, LB28, LB36, LHR100, LRB255, LRB355, etc. |

| Atlas Copco | D45, D50, D55, D60, D65, DM30, DM45, DM50, DM65, DM75, DML, AMM2, DMM2, DMM3, PV271, PV275, PV351, Flexi roc D60, Flexi roc D65, ROCL6, ROCL6-44, etc. |

| DELMAG | RH18W, etc. |

| JUNTTAN | PM25, PM26, etc. |

| Sandvik | AM50, DX800, DP1500, etc. |

| SANY | SR150, SR155, SR205, SR220, SR235, SR265, SR280, SR285, SR360, SR365, SR365RC10, SR405, SR415, SR485, etc. |

| XCMG | XR130, XR150, XR160, XR180, XR220, XR240, XR280, XR360, XR400, XR460, XR550, XR800, XRS1050, etc. |

| ZOOMLION | ZR125C, ZR140L, ZR160A-1, ZR160C, ZR160L, ZR220A, ZR220C, ZR240C, ZR280C, ZR280C-2, ZR300L, ZR360L, ZR380L, ZR400L, ZR450L, ZR500L, ZR550L, ZR650L, etc. |

| SUNWARD | SWDM40, SWDM60, SWDM80, SWDM130, SWDM160, SWDM160H2, SWDM200H, SWDM240, SWDM240H, SWDM240-2, SWDM260, SWDM280, SWDM300, SWDM300H, SWDM300H-2, SWDM360, SWDM360A, SWDM360H3, SWDM420, SWDM420V, SWDM450V, SWDM480, SWDM500, SWDM500V, SWDM550H2, SWDM600, SWDM800, SWDM1000, SWDM1280, etc. |

| JINTAI | SD12, SD20, SD22, SD28, SD30, SD32, SH25CW, SH46AW, etc. |

| Can’t find the model you need? Provide the parts manual we can customize for you! | |

FAQ

- Drilling Rig Parts Idler Factory Production Process Guide I

- Drilling Rig Parts Idler Factory Production Process Guide Ⅱ

- Regular Inspection and Maintenance of Idlers and Rollers: A Key to Long-Term Equipment Performance

Reviews

There are no reviews yet.