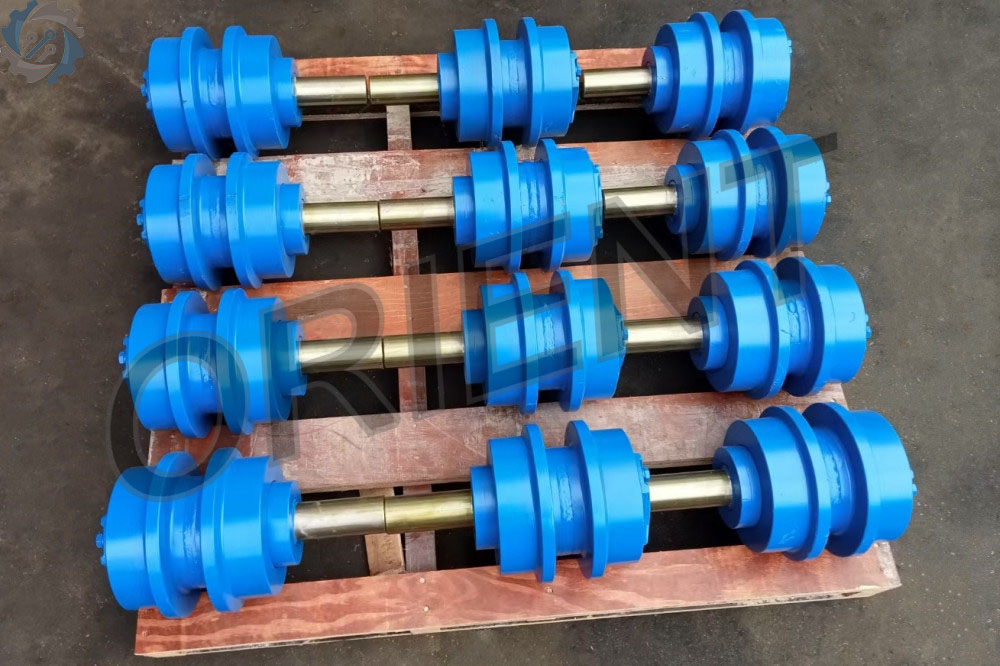

Bauer BG25C Carrier Roller Description

| Product Name | Bauer BG25C Upper Roller, Top Roller |

| Material | 40Mn2 |

| Colors | Black / Customer Requirement |

| Warranty time | 1 years/2500 working days |

| Certification | ISO9001 |

| Trade Terms | EXW, FOB, FCA, CFR, CIF, DAP, DDU |

| MOQ | 1 PCs |

| Delivery Time | 15-25days after payment |

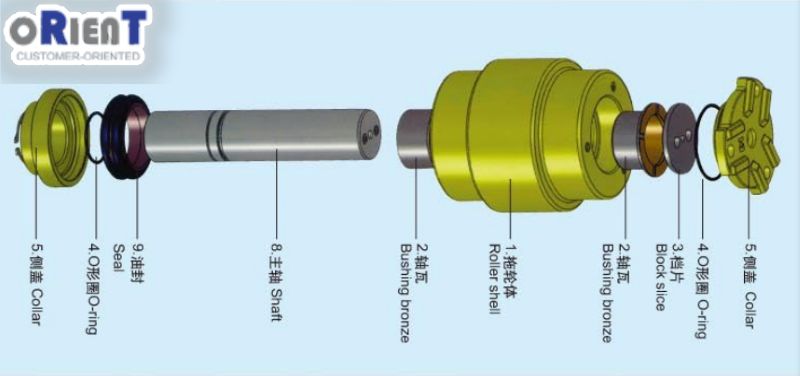

Bauer BG25C Upper Roller Structural

Production Process of Bauer BG25C Carrier Roller

Material Selection

- Choose high-quality alloy steel or carbon steel for strength, durability, and resistance to wear.

Machining

Cutting: Cut the raw material to size and shape with saws or plasma cutters.

Turning: Turn the pieces on a lathe to reach precise dimensions and a smooth finish.

Drilling and Boring: Drill and bore holes to fit bearings, shafts, and other components.

Milling: Mill the surfaces when specific features or contours are required.

Heat Treatment

Hardening: Quench and temper the rollers to increase hardness and durability.

Surface Hardening: Apply induction hardening or carburizing to strengthen the surface while keeping a tough core.

Grinding and Finishing

Grinding: Grind the rollers to precise dimensions and a smooth surface, ensuring proper fit in the piling rig.

Polishing: Polish the surface to lower friction and reduce wear.

Assembly

Bearing Installation: Insert bearings into the holes to support smooth rotation.

Sealing: Add seals to block dirt, debris, and moisture, extending service life.

Lubrication: Apply lubricant to ensure smooth operation and minimize wear.

Quality Control

Inspection: Inspect every roller for size accuracy, surface finish, and quality.

Testing: Test each unit to confirm smooth performance and strength under load.

Reviews

There are no reviews yet.