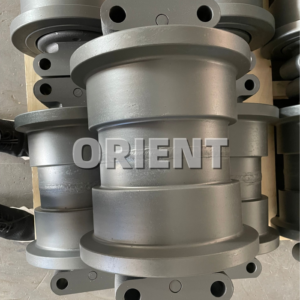

ATLAS COPCO DM45 TRACK ROLLER CPL FOR ROTARY BORING RIG

We are quality Undercarriage Parts Supplier!

Rotary drilling rigs are often equipped with track rollers, an important component used to support and balance the machine. The track rollers are located at the rear of the rotary drilling rig and are responsible for bearing and distributing the weight of the machine to ensure the stability and balance of the machine during construction.

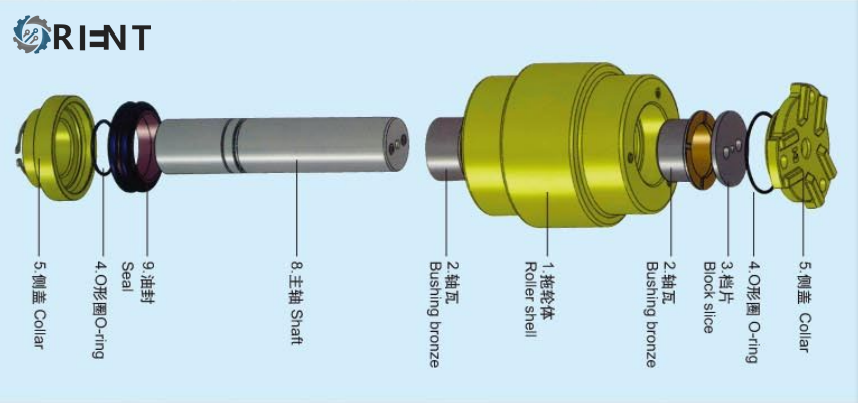

TRACK ROLLER STRUCTURE:

1. Outer ring: The outer ring of a track roller is typically made of high-quality steel or cast iron. It provides support and stability to the roller, ensuring smooth movement along the track.

2. Inner ring: The inner ring is usually made of hardened steel and is designed to fit snugly on the shaft or axle of the machine. It helps transmit the load from the machine to the track roller.

3. Rolling elements: The rolling elements, such as balls or cylindrical rollers, are positioned between the inner and outer rings. They enable the track roller to roll smoothly along the track, reducing friction and wear.

4. Seals and shields: Track rollers often have seals or shields to protect the rolling elements from contaminants, such as dust, dirt, and moisture. These protective features help prolong the lifespan and performance of the track roller.

5. Lubrication: Some track rollers are equipped with grease fittings or lubrication holes to facilitate proper lubrication. Lubrication is essential to reduce friction and heat generation, ensuring smooth operation and preventing premature wear.

RECOMMEND PRODUCTS Atlas Copco DM45 Track Roller CPL for Rotary Boring Rig

Other related hot products that may be of interest to you.

Track Shoe | Track Link | Upper Roller | Sprocket | Idler |

MORE PRODUCT RELATED VIDEOS

Reviews

There are no reviews yet.