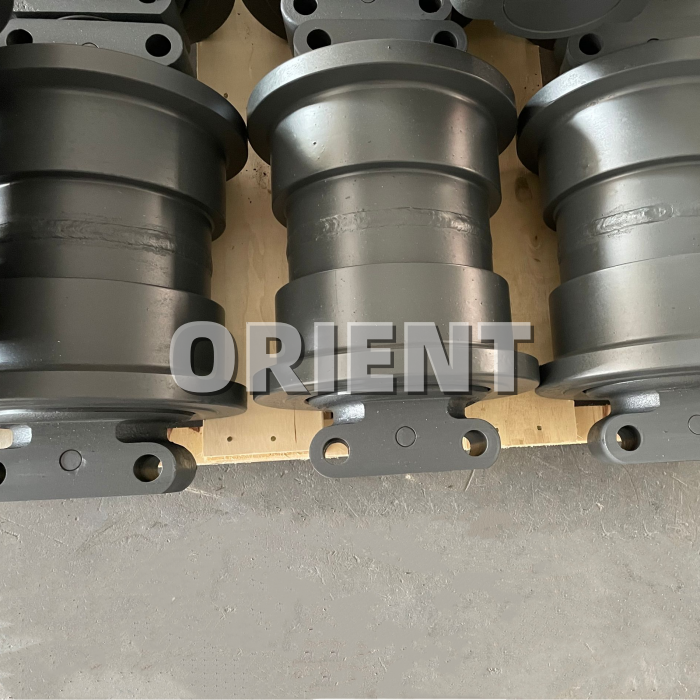

LH696 TRACK ROLLER FOR PILING RIG

Rotary drilling rigs are often equipped with track rollers, an important component used to support and balance the machine. The track rollers are located at the rear of the rotary drilling rig and are responsible for bearing and distributing the weight of the machine to ensure the stability and balance of the machine during construction.

Product Information:

The Track Roller, also known as the Bottom Roller or Lower Roller, is a crucial component of drilling rig undercarriage systems. It is designed to provide smooth movement and support for heavy machinery in demanding environments, ensuring the efficiency and stability of the equipment.

Material:

Made from 40Mn2 high-strength steel, the roller offers excellent durability and resistance to wear and tear, ensuring long-lasting performance under heavy loads.

Finish:

The roller features a smooth finish, which helps reduce friction and improve the overall performance of the machinery.

Manufacturing Process:

The product undergoes a meticulous manufacturing process that includes forging, heat treatment (quenching and tempering), and welding to ensure the highest standards of strength and reliability.

Warranty:

This product comes with a 1-year warranty or 2500 working days, providing confidence in its long-term performance and reliability.

Certification:

Certified with ISO9001, ensuring that the roller meets international quality and manufacturing standards.

FOB Price:

Negotiable, based on order quantity and requirements.

MOQ (Minimum Order Quantity):

1 PC

Delivery Time:

15-25 days after payment, ensuring a timely supply for your needs.

Packaging:

The roller is carefully packed in pallets or plywood cases, ensuring safe delivery and protection during transit.

Payment Terms:

We offer flexible payment options, including TT, LC, or negotiation based on your preference.

Applicable Industries:

Ideal for use in industries such as construction, machinery repair, manufacturing, retail, energy, mining, and construction work locations.

Global Reach:

Our track rollers are supplied to various countries, including Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, United Arab Emirates, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Nigeria, Malaysia, and Spain.

OUR TRACK ROLLER FEATURE

Roller Types: Cast Iron Roller & Steel Roller

Roller Types: Cast Iron Roller & Steel Roller

- high strength

- Low wear & tear

- Highprecise

FAQ

- Are you a manufacturer or trading company?

– Yes, we have factories and we are the leading manufacturer in China. Welcome if you have plan to visit our

factory and inspect the products. - What services can you provide?

– Pre/after sales technical support - Warranty

-1 year/2500 working hours, during this period damage will be resent for free - What is your MOQ?

-It depends on what you are buying.

Samples are acceptable and LCL(less than the weight of a container) is OK.

(Tips: the more orders you place, the less you’ll have to share the overhead costs per unit weight, which is more economical.) - How can I be sure the part will fit my machine?

-Notify us correct machine model / part number. Or measure the parts give us dimensions or drawing. - I have no experience in buying goods from China, can you help me?

-Of course, my company has a professional operation department with more than 10 years of import and export experience, and has cooperated forwarders all over the world, we will advise you until you get the package.

RECOMMEND PRODUCTS

Other related hot products that may be of interest to you.

Track shoe | Track Link | Upper roller | Sprocket | Idler |

MORE PRODUCT RELATED VIDEOS:

Reviews

There are no reviews yet.