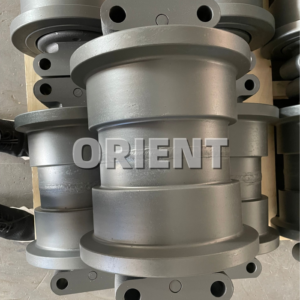

SANY SR485 TRACK ROLLER FOR PILING RIG MACHINE

When choosing a durable rotary drilling rig track roller, there are several factors to consider:

1. Material: Look for track rollers made from high-quality materials such as forged steel or cast iron. These materials are known for their durability and ability to withstand heavy loads and harsh working conditions.

2. Design: Consider the design of the track roller, including the shape and size of the roller surface. Look for rollers with a larger surface area, as this can distribute the load more evenly and reduce wear and tear.

3. Heat treatment: Ensure that the track roller has undergone proper heat treatment processes such as quenching and tempering. This improves the hardness and strength of the roller, making it more resistant to wear and extending its lifespan.

4. Sealing system: Check the sealing system of the track roller to prevent the entry of dirt, dust, and moisture. A good sealing system will help protect the roller from corrosion and reduce the risk of premature failure.

5. Compatibility: Make sure that the track roller is compatible with your specific rotary drilling rig model. Check the dimensions and specifications provided by the manufacturer to ensure a proper fit.

6. Reputation of the manufacturer: Choose track rollers from reputable manufacturers known for producing high-quality products. Read customer reviews and seek recommendations from industry professionals to ensure reliability and durability.

7. Warranty: Look for track rollers that come with a warranty. A warranty indicates the manufacturer’s confidence in the durability and performance of their product.

By considering these factors, you can choose a durable rotary drilling rig track roller that will withstand the rigors of heavy-duty drilling operations and provide long-lasting performance.

My company can meet all the above requirements for high-quality accessories and will be a good choice for you.

RECOMMEND PRODUCTS SANY SR485 Track Roller for Piling Rig Machine

Other related hot products that may be of interest to you.

Track Shoe | Track Link | Upper Roller | Sprocket | Idler |

SUPPORT MODEL

| BRAND | MODEL |

| Bauer | BG12, BG18, BG20, BG20H, BG24, BG25, BG25C, BG25H, BG26, BG28, BG28V, BG30, BG34, BG36, BG36H, BG39, BG40, etc. |

| Soilmec | SR30, SR40, SR60, SR65, SR70, SR75, SR80, SR80C, SR90, SR95, SR100, R16, R208, R312, R415, R618, R620, R622, R622HD, R724, R725, R930, etc. |

| Casagrande | B180, B180HD, B250, B250XP, B300, C50, C60, C250, etc. |

| IMT | AF18, AF180, AF190E, AF190F, AF200, AF215, AF250E, AF250F, AF270, AF270E, AF280, AF300, AF300E, AF350D, etc. |

| CMV | TH18-65, TH20, TH32, etc. |

| Mait | HR100, HR260, etc. |

| Sany | SR150, SR155, SR205, SR220, SR235, SR265, SR280, SR285, SR360, SR365, SR365RC10, SR405, SR415, SR485, etc. |

| Xcmg | XR130, XR150, XR160, XR180, XR220, XR240, XR280, XR360, XR400, XR460, XR550, XR800, XRS1050, etc. |

| Zoomlion | ZR125C, ZR160C, ZR240C, ZE280C, ZR160L, ZR160A-1, ZR220C, ZR280C-2, ZR300L, ZR360L, ZR380L, ZR400L, ZR450L, ZR500L, ZR650L, ZR140L, ZR550L, ZR220A, etc. |

| Sunward | SWDM40, SWDM60, SWDM80, SWDM130, SWDM160, SWDM160H2, SWDM200H, SWDM240, SWDM240H, SWDM240-2, SWDM260, SWDM280, SWDM300, SWDM300H, SWDM300H-2, SWDM360, SWDM360A, SWDM360H3, SWDM420, SWDM420V, SWDM450V, SWDM480, SWDM500, SWDM500V, SWDM550H2, , SWDM600, SWDM800, SWDM1000, SWDM1280, etc. |

| Liebherr | LB24, LB28, LB36, etc. |

| Atlac Copco | FLEXIROC D55, etc. |

| Sandvik | DX800, etc. |

Note: we can also produce them according to clients drawings and requirements.

MORE PRODUCT RELATED VIDEOS

Reviews

There are no reviews yet.