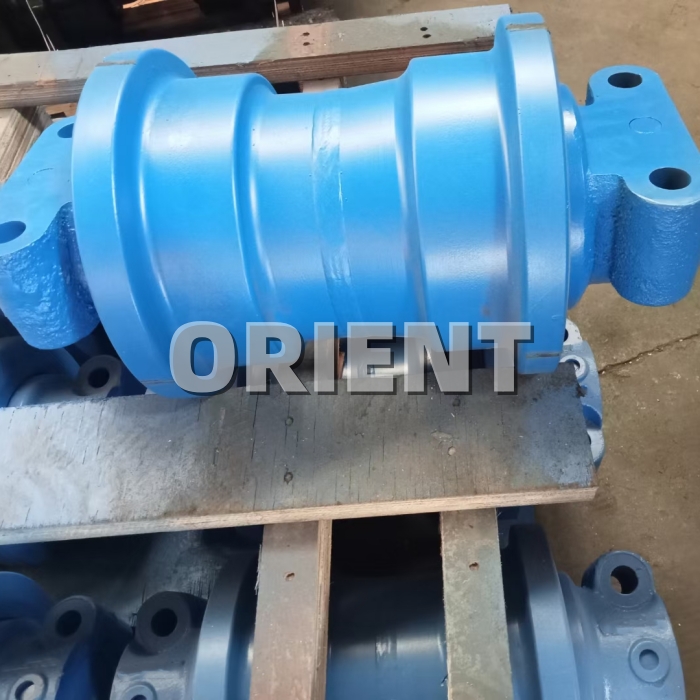

ZOOMLION ZR125C DOWN ROLLER FOR PILING RIG

Drilling Rig Undercarriage Parts Maintenance Method.

Maintaining the undercarriage parts of a drilling rig is crucial for ensuring its optimal performance and longevity. Here are some recommended maintenance methods for drilling rig undercarriage parts:

- Regular Inspections

- Cleaning

- Lubrication

- Track Tension Adjustment

- Track Shoe Replacement

- Component Alignment

- Track Shoe Grouser Maintenance

- Track Frame Cleaning

- Regular Maintenance Schedule

- Proper Operator Training

Remember to always consult the manufacturer’s guidelines and recommendations for specific maintenance procedures and intervals for your drilling rig’s undercarriage parts.

EXHIBITION PHOTOS

RECOMMEND PRODUCTS

Track Shoe | Track Link | Upper Roller | Sprocket | Idler

MORE PRODUCT-RELATED VIDEOS

Reviews

There are no reviews yet.