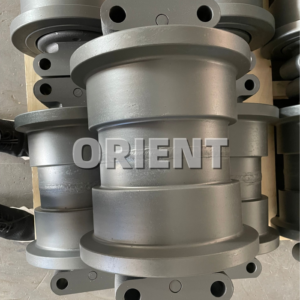

CASAGRANDE B180HD DOWN ROLLER FOR DRILLING RIG

MAINTAINING THE UNDERCARRIAGE PARTS OF A DRILLING RIG IS CRUCIAL FOR ENSURING ITS OPTIMAL PERFORMANCE AND LONGEVITY.

Here are some recommended maintenance methods for drilling rig undercarriage parts:

1. Regular Inspections: Conduct routine inspections to identify any signs of wear, damage, or misalignment in the undercarriage components. Inspect the rollers, idlers, sprockets, track shoes, and track links for any abnormalities.

2. Cleaning: Regularly clean the undercarriage parts to remove dirt, debris, and other contaminants that can cause premature wear. Use a pressure washer or a hose with a nozzle to thoroughly clean the components.

3. Lubrication: Proper lubrication is essential for reducing friction and extending the lifespan of undercarriage parts. Follow the manufacturer’s recommendations for lubrication intervals and use high-quality lubricants that are suitable for the specific components.

4. Track Tension Adjustment: Regularly check and adjust the track tension to ensure proper alignment and prevent excessive wear. Improper track tension can lead to accelerated wear of the undercarriage parts.

5. Track Shoe Replacement: Monitor the condition of the track shoes and replace them when they are worn beyond the recommended limits. Worn track shoes can cause uneven wear on other undercarriage components.

6. Component Alignment: Ensure proper alignment of the undercarriage components to avoid unnecessary stress and premature wear. Misaligned components can cause uneven wear and reduce the overall performance of the drilling rig.

7. Track Shoe Grouser Maintenance: Check the condition of the track shoe grousers and replace them if they are worn or damaged. Worn grousers can affect the traction and stability of the drilling rig.

8. Track Frame Cleaning: Regularly clean the track frame to remove any accumulated dirt, rocks, or debris. Accumulated debris can cause damage to the undercarriage parts and affect the overall performance of the drilling rig.

9. Regular Maintenance Schedule: Develop a maintenance schedule and adhere to it strictly. This should include regular inspections, cleaning, lubrication, and any necessary repairs or replacements.

10. Proper Operator Training: Ensure that the operators are trained on proper operation and maintenance procedures for the drilling rig’s undercarriage parts. Proper operation and care can significantly reduce wear and extend the lifespan of the components.

Remember to always consult the manufacturer’s guidelines and recommendations for specific maintenance procedures and intervals for your drilling rig’s undercarriage parts.

RECOMMEND PRODUCTS

Other related hot products that may be of interest to you.

Track Shoe | Track Link | Upper Roller | Sprocket | Idler

MORE PRODUCT RELATED VIDEOS

Reviews

There are no reviews yet.