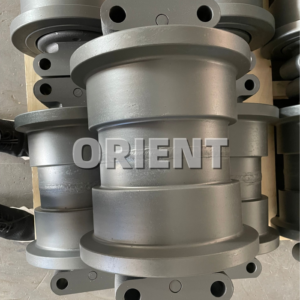

Details of the MBG12 track roller

| Goods description | Track roller, bottom roller |

| Suitable model | Bauer MBG12 |

| Machine type | Drilling rig, Ductile Pile |

| Material | 40Mn2 |

| Colour | Black, blue, or as required |

| Technique | Forging |

| Heat treatment | Quenching and tempering, surface hardening |

| Condition | 100% brand new |

| Packing | Plywood pallet or wooden pallet |

| Loading port | Yantai, Qingdao, Shanghai, Guangzhou, Yiwu, etc. |

| Trade term | EXW, FOB, CFR, CIF, DDU, DAP |

| Warranty time | 1 year |

| MOQ | 1 piece |

Function of the MBG12 track roller

- Support the weight. The track roller transfers the weight of the drilling rig to the tracks, which then transfers the weight to the ground.

- Guide the tracks. Track roller guides the tracks along the predetermined path to ensure the smooth travel of the machine.

- Bear impact and friction. When the rollers travel on uneven roads, they will be impacted by the ground and also bear the friction between the tracks and the wheel rims.

- Prevent derailment. The structural design of the track roller can prevent the tracks from detaching from the wheels during movement, ensuring the normal operation of the machine.

Inner structure of the MBG12 track roller

Roller body, shaft, bushing, roller cap, floating oil seal, o-ring, etc.

Shipment photos

Related products

- MBG12 track shoe/track pad

- MBG12 track chain/track link

- MBG12 carrier roller/top roller

- MBG12 sprocket/drive wheel

- MBG12 idler/guide wheel

Maintenance of the track roller in daily use

- Lubricate regularly. Lubrication is the lifeblood of the track roller. Using the correct lubricant and lubricating according to the recommended maintenance schedule can reduce friction, prevent corrosion and wear, and ensure smooth operation of the rollers.

- Regular inspection. Regularly check the wear of the track roller, including the thickness of the rims, whether the rotation is smooth, etc. Those with severe wear should be replaced in time.

- Replace in time. If the track roller leaks oil, rotates abnormally, or the rims are worn too thin, they should be replaced in time to avoid further damage.

- Regular cleaning. After use in environments such as mud, sand, and chemicals, the track roller and tracks should be cleaned in time to prevent wear and corrosion.

- Pay attention to the floating oil seal. If the floating oil seal leaks oil, replace them in time to maintain good sealing.

Other brands

| Undercarriage Parts for Rotary Drilling Rig | |

| Brands | Models |

| Bauer | BG12, BG18, BG20, BG20H, BG22H, BG24, BG24H, BG25, BG25C, BG25H, BG26, BG28, BG28V, BG30, BG33H, BG34, BG36, BG36H, BG39, BG40, GB34, GB50, MBG12, MBG24, RTG RG 22S, RTG RM20, etc. |

| Soilmec | SR30, SR40, SR60, SR65, SR70, SR75, SR80, SR80C, SR90, SR95, SR100, R16, R208, R312, R415, R515, R618, R620, R622, R622HD, R724, R725, R930, etc. |

| Casagrande | B125, B180, B180HD, B250, B250XP, B300, B400, C6XP, C7XP, C25, C30, C50, C60, C60HD, C90, C250, C400, C600, C600ZN, etc. |

| IMT | AF10, AF12, AF18, AF35, AF180, AF190, AF200, AF215, AF250E, AF250F, AF270, AF270E, AF280, AF290, AF300, AF300E, AF350D, etc. |

| CMV | TH15-50, TH18-65, TH20, TH32, MK1200M, etc. |

| Mait | HR100, HR180, HR260, HR360, MC180, etc. |

| LIEBHERR | LB24, LB28, LB36, LHR100, LRB255, LRB355, etc. |

| Atlas Copco | D45, D50, D55, D60, D65, DM30, DM45, DM50, DM65, DM75, DML, AMM2, DMM2, DMM3, PV271, PV275, PV351, Flexi roc D60, Flexi roc D65, ROCL6, ROCL6-44, etc. |

| DELMAG | RH18W, etc. |

| JUNTTAN | PM25, PM26, etc. |

| Sandvik | AM50, DX800, DP1500, etc. |

| SANY | SR150, SR155, SR205, SR220, SR235, SR265, SR280, SR285, SR360, SR365, SR365RC10, SR405, SR415, SR485, etc. |

| XCMG | XR130, XR150, XR160, XR180, XR220, XR240, XR280, XR360, XR400, XR460, XR550, XR800, XRS1050, etc. |

| ZOOMLION | ZR125C, ZR140L, ZR160A-1, ZR160C, ZR160L, ZR220A, ZR220C, ZR240C, ZR280C, ZR280C-2, ZR300L, ZR360L, ZR380L, ZR400L, ZR450L, ZR500L, ZR550L, ZR650L, etc. |

| SUNWARD | SWDM40, SWDM60, SWDM80, SWDM130, SWDM160, SWDM160H2, SWDM200H, SWDM240, SWDM240H, SWDM240-2, SWDM260, SWDM280, SWDM300, SWDM300H, SWDM300H-2, SWDM360, SWDM360A, SWDM360H3, SWDM420, SWDM420V, SWDM450V, SWDM480, SWDM500, SWDM500V, SWDM550H2, SWDM600, SWDM800, SWDM1000, SWDM1280, etc. |

| JINTAI | SD12, SD20, SD22, SD28, SD30, SD32, SH25CW, SH46AW, etc. |

| Can’t find the model you need? Provide parts manual we can customize for you! | |

Reviews

There are no reviews yet.