LIEBHERR LHR100 Tumbler Drive for Rig Machine

Product Description:

LIEBHERR LHR100 are made from durable materials such as 40Mn2 and 35SiMn to increase their ability to withstand the harsh conditions of drilling operations. We accept OEM and can customize undercarriage components to your specific needs. And our MOQ is flexible, only 1 piece. This means you can order as many undercarriage parts as you need without worrying about overstocking or tying up your budget. When it comes to drilling rig undercarriage parts, quality and reliability are paramount. Trust us to deliver superior products that will keep your rig running smoothly and efficiently.

Drilling rig undercarriage parts:

Track pad

Track chain assembly

Carrier roller

Bottom roller

Idler

Sprocket drive

Quality Control:

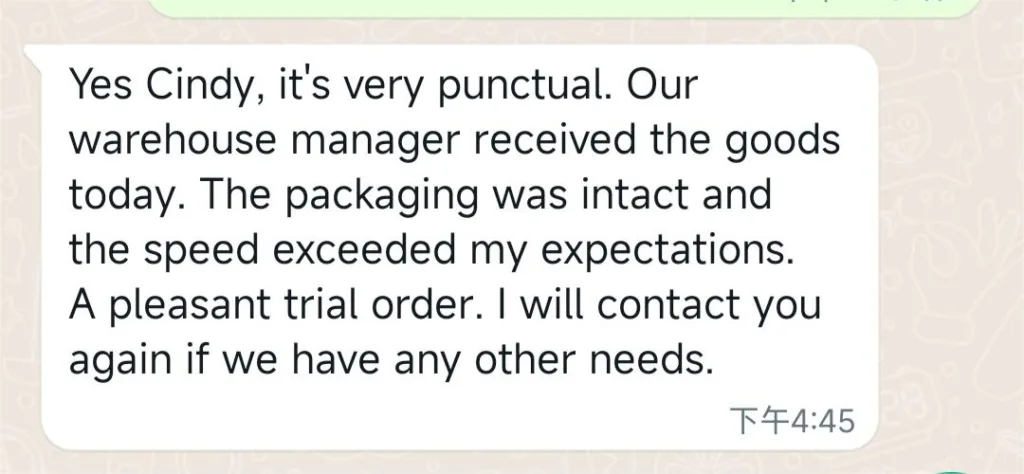

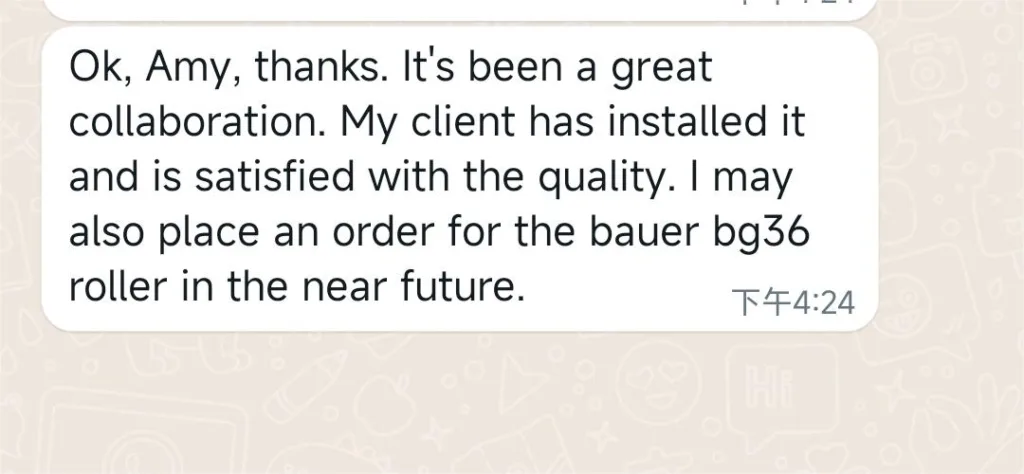

Client Feedback:

Drilling Rig Undercarriage Maintenance:

1. When stopping work in a short period of time, a small amount of compressed air should be given to prevent sediment from invading the inside of the drilling rig impactor. If the drilling rig operation is stopped for a long time, the impactor should be raised 1-2 meters away from the bottom of the hole and fixed.

2. Always check the lubricating oil condition of the wind motor.

3. When the working surface is immersed in water, use a large-diameter drill bit when opening the hole and insert the drill pipe so that the drill pipe is 1-2 meters above the water surface to prevent mud and rock slag from falling into the hole.

4. No reversal is allowed during drilling operations to prevent the drill pipe from falling into the hole;

5. Always check the water and gas pipelines of the crawler drilling rig to see if the bolts and nuts of each accessory are tight.

Reviews

There are no reviews yet.