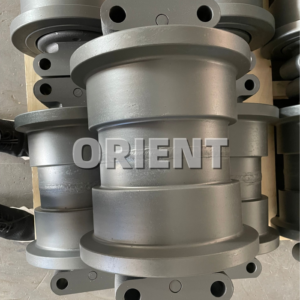

IMT AF18 BOTTOM ROLLER FOR PILING RIG

The production process of drilling rig track rollers typically involves several steps, including:

1. Material selection

2. Cutting and shaping

3. Heat treatment

4. Machining

5. Surface treatment

6. Assembly

7. Quality control

Once the track rollers pass the quality control checks, they are packaged and ready for shipment to drilling rig manufacturers or distributors.

WHY US?

- Factory

- Professional engineer

- 10+ years of production experience

- 8+ years of import and export experience

- Pre/after-sales technical support

- Performance: Quality parts,OEM quality

- Cost-effectiveness: Durable & Reasonable price

- Certificate: ISO9001

- Warranty: 1 year/2500 working hours

RECOMMEND PRODUCTS

Other related hot products that may be of interest to you.

Track shoe | Track Link | Upper roller | Sprocket | Idler |

MORE PRODUCT RELATED VIDEOS

Reviews

There are no reviews yet.