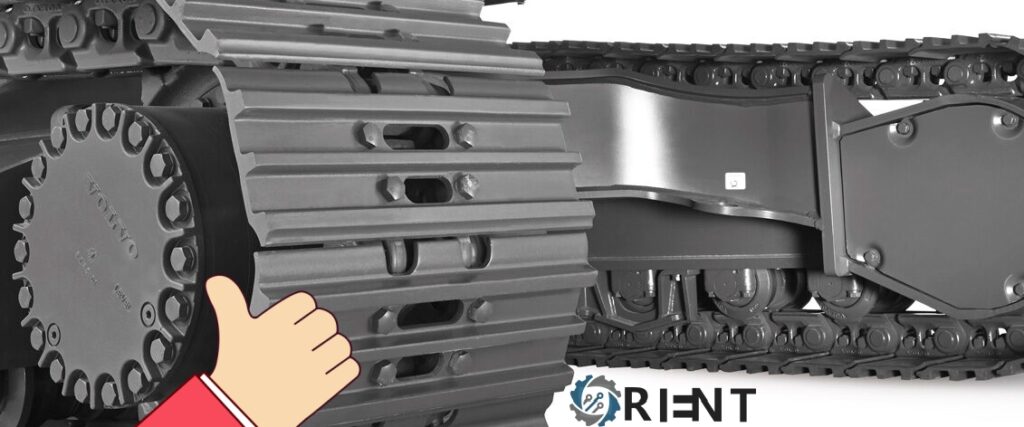

LH697B TRACK ROLLER FOR PILING MACHINE

MAINTAINING THE UNDERCARRIAGE PARTS OF A DRILLING RIG IS CRUCIAL FOR ENSURING ITS OPTIMAL PERFORMANCE AND LONGEVITY.

Here are some recommended maintenance methods for drilling rig undercarriage parts:

1. Regular Inspections

2. Cleaning

3. Lubrication

4. Track Tension Adjustment

5. Track Shoe Replacement

6. Component Alignment

7. Track Shoe Grouser Maintenance

8. Track Frame Cleaning

9. Regular Maintenance Schedule

10. Proper Operator Training

Remember to always consult the manufacturer’s guidelines and recommendations for specific maintenance procedures and intervals for your drilling rig’s undercarriage parts.

WHY US?

- Factory

- 10+ years of production experience

- 8+ years of import and export experience

- Pre-sales technical support

- Performance: OEM quality

- Cost-effectiveness: Durable & Reasonable price

- Certificate: ISO9001

- Warranty: 1 year/2500 working hours

- Business Scope: Drilling Rig, Crawler Crane, Excavators, Bulldozers

RECOMMEND PRODUCTS

Track Shoe | Track Link | Upper Roller | Sprocket | Idler

MORE PRODUCT-RELATED VIDEOS

Reviews

There are no reviews yet.