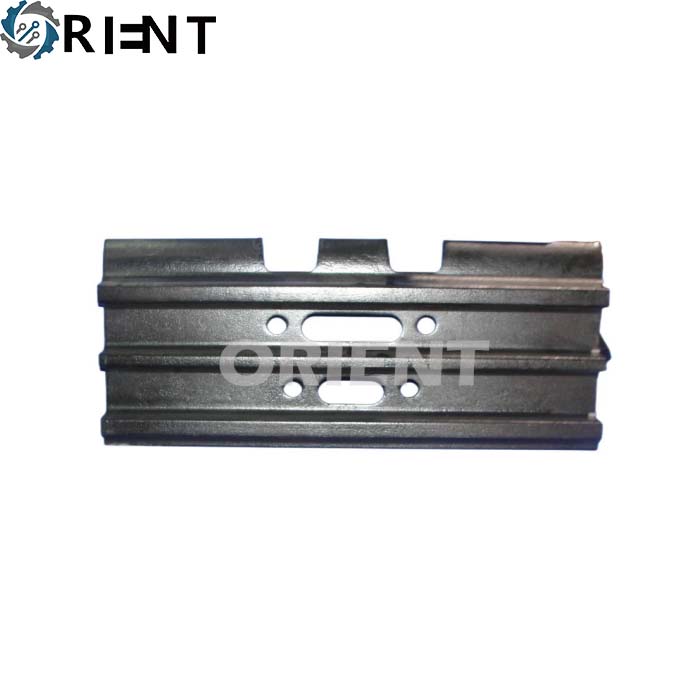

Our rotary drilling rigs track shoes are made of high-quality raw materials with high hardness, wear resistance and long service life, saving costs for customers.

Technical Details of Bauer MC64 MC96 MC128 Track Shoe:

- Material: 25MnB

- Color: Black / Customer Requirement

- Technique: Heat Treatment

- Certification: ISO9001

- Inspection Method: MT, UT…

- Package Detail: Pallet / Plywood Case

- Product Standard: JIS, ASTMA128, GB/T5680-2010

Production Process of Bauer MC64 MC96 MC128 Crawler Crane Track Shoe:

Cutting → Punching → Heat Treatment → Straightening → Painting → Inspection → Packing

Track Shoe Material & Design Features:

- Material: Track shoes are typically made from high-strength steel to ensure they can handle the heavy load-bearing and harsh conditions encountered during construction and lifting operations.

- Design Features: Bauer’s track shoes often have additional reinforcements or anti-wear features, including hard-facing or wear-resistant coatings for extended service life, especially when operating on abrasive surfaces.

Additional Considerations for Bauer MC Series:

- Track Tensioning System: Bauer cranes are equipped with hydraulic systems that allow for adjustable track tension, ensuring the track shoes remain tight and functional under varying operating conditions.

- Track Shoe Pads and Inserts: Depending on the working environment (e.g., soft ground vs. hard ground), Bauer offers interchangeable track pads or inserts that can be attached to the track shoes to reduce ground pressure or improve traction.

Replacement and Maintenance:

- Wear and Tear: Track shoes on a crawler crane are subject to wear due to the constant friction against the ground and the weight of the machine. Regular inspection and timely replacement of track shoes are crucial to ensure the crane’s stability and performance.

- Parts Availability: Bauer provides OEM (Original Equipment Manufacturer) track shoes and other components for their cranes. It’s essential to use the correct parts specified for the MC series to maintain optimal performance.

If you need to replace or upgrade the track shoes for your Bauer MC64, MC96, or MC128, it’s recommended to consult with an authorized Bauer dealer or service center. They can provide specific part numbers and options tailored to your crane’s needs and your job site conditions.

Brand and Model of Rotary Drilling Rig Track Shoes We Can Produce:

| Suitable Brands & Models | |

| Undercarriage Parts for Rotary Drilling Rig | |

| Brands | Models |

| Bauer | BG12, BG15, BG18, BG20, BG20H, BG22, BG22H, BG24, BG24H, BG25, BG25C, BG25H, BG26, BG28, BG28V, BG30, BG33H, BG34, BG36, BG36H, BG39, BG40, BG45, BG50, GB34, GB50, MBG12, MBG24, RTG RG22S, RTG RM20, UW110, etc. |

| Soilmec | SR13, SR15, SR20, SR30, SR40, SR60, SR65, SR70, SR75, SR80, SR80C, SR90, SR95, SR100, R16, R208, R208 (HD), R208, R312, R312/200, R312HD, R415, R515, R618, R620, R622, R622HD, R724, R725, R825, R930, etc. |

| Casagrande | B80, B125, B170, B180, B180HD, B250, B250XP, B300, B400, C6XP, C7XP, C8, C25, C30, C50, C60, C60HD, C90, C250, C400, C600, C600ZN, etc. |

| IMT | AF10, AF12, AF18, AF35, AF180, AF190E, AF190F, AF200, AF215, AF250E, AF250F, AF270, AF270E, AF280, AF290, AF300, AF300E, AF350D, A215, etc. |

| CMV | TH15-50, TH18-65, TH20, TH32, MK1200M, etc. |

| MAIT | HR100, HR110, HR130, HR150, HR180, HR260, HR360, MC180 etc. |

| LIEBHERR | LB24, LB28, LB36, LHR100, LRB255, LRB355, etc. |

| Atlas Copco | D45, D50, D55, D60, D65, DM30, DM45, DM45E, DM45HP, DM50,DM65 DM50LP, DM75, DMH, DMH/XL2600, DML, DML-HP, DML-LP, DMM2, DMM3, ECM590, EPIROC D50, EPIROC D55, FLEXI ROC D55, FLEXI ROC D60, FLEXI ROC D65, PV271, PV271D, PV275, PV275E, PV351, PV351D, PV351E, PVE5021, ROCL6, ROCL6-44, ROCL6-5M, AMM2, SmartRoc D65, etc. |

| Sandvik | AM50, DX700,DX800, DP1500, Leopard DI650I, etc. |

| SANY | SR150, SR155, SR205, SR220, SR235, SR265, SR280, SR280C, SR285, SR285R, SR360, SR365, SR365RC10, SR400R, SR405R, SR415, SR485, Leopard DI650I, etc. |

| XCMG | XR130, XR150, XR160, XR180, XR220, XR240, XR280, XR360, XR400, XR460, XR550, XR800, XRS1050, XR3200, SR280C, etc. |

| ZOOMLION | ZR125C, ZR160C, ZR240C, ZE280C, ZR360C, ZR ZR160L, ZR160A-1, ZR220C, ZR280C, ZR280C-2, ZR300L, ZR360L, ZR380L, ZR400L, ZR450L, ZR500L, ZR650L, ZR140L, ZR550L, ZR220A, etc. |

| SUNWARD | SWDM40, SWDM60, SWDM80, SWDM130, SWDM160, SWDM160H2, SWDM200H, SWDM240, SWDM240H, SWDM240-2, SWDM260, SWDM280, SWDM300, SWDM300H, SWDM300H-2, SWDM360, SWDM360A, SWDM360H3, SWDM420, SWDM420V, SWDM450V, SWDM480, SWDM500, SWDM500V, SWDM550H2, SWDM600, SWDM800, SWDM1000, SWDM1280,SA175 etc. |

| FURUKAWA | HCR1200, HCR1200 DS III, HCR1201 DS III, HCR1202 DS III, HCR1203 DS III, HCR1800, HCR900-XSII, HCR901-XSII, HCR902-XSII, HCR903-XSII,HCR904-XSII, ,DCR20, ,DCR21, DCR22, DCR23, DCR24 |

| JINTAI | SD12, SD20, SD22, SD28, SD30, SD32, SH25CW, SH36E, SH-36W, SH46AW, etc. |

| Hyundai | Everdigm D700, Everdigm D800,etc. |

| JUNTTAN | PM25, PM26, etc. |

| SENNEBOGEN | SR40T, 860M, etc. |

| DELMAG | RH18W, etc. |

| Epiroc | DML 1, etc. |

| KLEMM | 806-4, etc. |

| Solitek | S-60, etc. |

| TESCAR | CF06, etc. |

| Comacchio | MC 800-S, etc. |

| Can’t find the model you need? Provide parts manual we can customize for you! | |

If you have any need of rotary drilling rig track shoes, please contact us freely!

Reviews

There are no reviews yet.