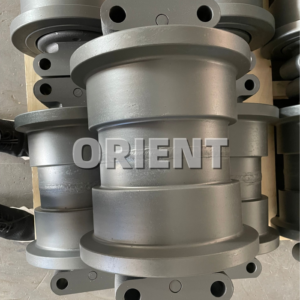

BAUER BG26 TRACK ROLLER FOR DRILLING RIG

| Product Information | Drilling Rig Undercarriage Parts/Track roller |

| Material | 40Mn2 |

| Finish | Smooth |

| Colors | Black / Customer Requirement |

| Technique | Forging → Heat treatment (quenching and tempering) → Welding |

| Warranty time | 1 years/2500 working days |

| Certification | ISO9001 |

| FOB Price | Negotiate |

| MOQ | 1 PCs |

| Delivery Time | 15-25days after payment |

| Package | Pallet / Plywood Case |

| Payment Term | TT;LC;Negotiate |

WHAT’S A TRACK ROLLER?

The track roller is typically made of high-strength steel and is designed to withstand heavy loads, shocks, and vibrations. It is mounted on the track frame of the piling rig and rotates on a shaft or pin, allowing the tracks to move smoothly.

The main function of the track roller is to distribute the weight of the piling rig evenly across the tracks, reducing ground pressure and preventing excessive wear on the tracks. It also helps in maintaining stability and maneuverability of the machine during operation.

Track rollers are subjected to significant stress and wear due to the nature of the work performed by piling rigs. Therefore, they are built to be durable and resistant to abrasion, ensuring reliable performance and extended service life.

RECOMMEND PRODUCTS

Other related hot products that may be of interest to you.

Track shoe | Track Link | Upper roller | Sprocket | Idler |

MORE PRODUCT RELATED VIDEOS:

Reviews

There are no reviews yet.