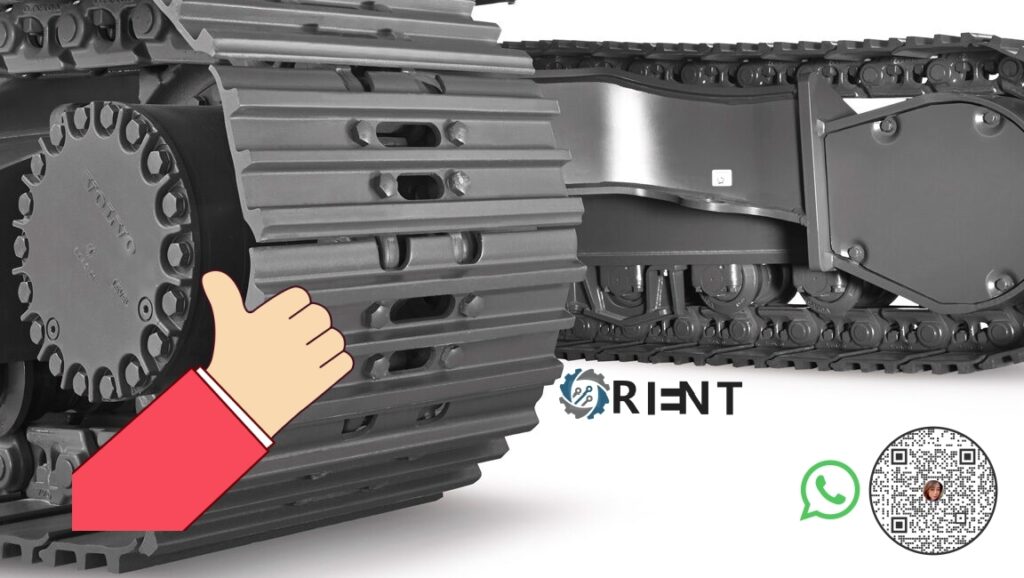

BAUER BG20H TRACK ROLLER FOR DRILLING RIG

Why do drilling rig track rollers break?

1. Overloading

Excessive weight or load on the drilling rig can cause the track rollers to break. If the rig is carrying more weight than it can handle, the rollers may not be able to withstand the stress, leading to failure. Solution: Follow the correct instructions on the drilling rig and avoid overloading.

2. Wear and tear

Continuous use and harsh operating conditions can cause the track rollers to wear out over time. The constant friction and impact from the rough terrain can weaken the rollers, eventually leading to breakage. Solution: When the track roller is damaged, please replace it with a new one in time to avoid damage to more parts.

3. Lack of maintenance

Inadequate or irregular maintenance can contribute to the failure of track rollers. If the rollers are not properly lubricated, cleaned, or inspected, they may become damaged or worn, increasing the likelihood of breakage. Solution: Perform regular and correct maintenance of track rollers.

4. Manufacturing defects

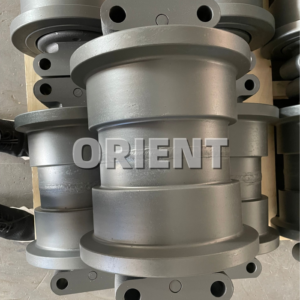

Occasionally, track rollers may have manufacturing defects that make them more prone to breakage. This could be due to poor quality control during the production process or faulty materials used in the construction of the rollers. Solution: Don’t buy substandard rollers just for temporary benefits. We should choose high-quality suppliers as long-term partners.

5. Improper installation

Incorrect installation or improper alignment of the track rollers can cause them to bear uneven loads, leading to stress concentrations and eventual failure. Solution: Seek installation from experienced technical experts rather than haphazard installation.

6.Impact damage

The drilling rig may encounter unexpected impacts or collisions during operation, such as hitting rocks or other obstacles. These impacts can cause severe damage to the track rollers, resulting in breakage. Solution: Provide professional knowledge training to operators to avoid irregular operations.

7. Corrosion

If the drilling rig operates in corrosive environments, such as saltwater or chemical-rich areas, the track rollers may corrode over time. Corrosion weakens the structural integrity of the rollers, making them more susceptible to breakage. Solution: Operation in harsh environments should be avoided as much as possible.

To prevent track roller breakage, regular maintenance, proper installation, and adherence to weight limits are essential. Additionally, using high-quality track rollers and avoiding harsh operating conditions can help prolong their lifespan.

RECOMMEND PRODUCTS

Other related hot products that may be of interest to you.

Track shoe | Track Link | Upper roller | Sprocket | Idler |

MORE PRODUCT RELATED VIDEOS Bauer BG20H Track Roller

Reviews

There are no reviews yet.