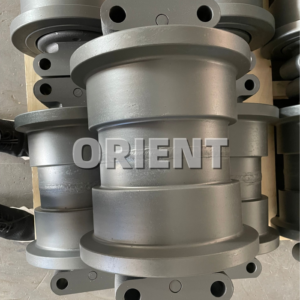

SOILMEC R16 TRACK ROLLER FOR ROTARY DRILLING RIG

The structure and function of track rollers

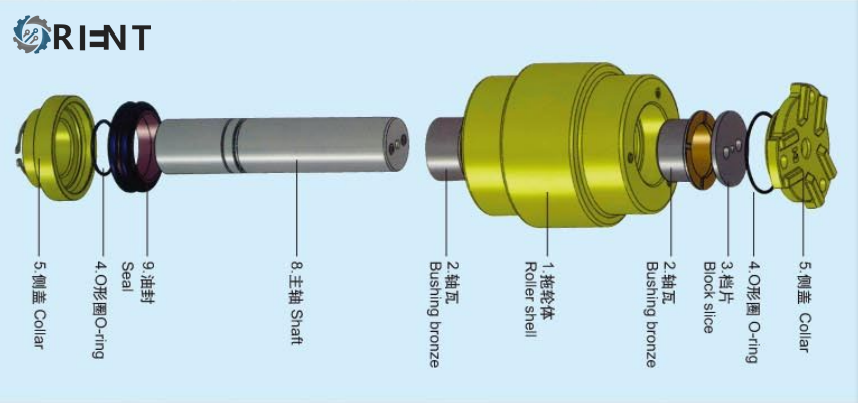

STRUCTURE

1. Outer ring: The outer ring of a track roller is typically made of high-quality steel or cast iron. It provides support and stability to the roller, ensuring smooth movement along the track.

2. Inner ring: The inner ring is usually made of hardened steel and is designed to fit snugly on the shaft or axle of the machine. It helps transmit the load from the machine to the track roller.

3. Rolling elements: The rolling elements, such as balls or cylindrical rollers, are positioned between the inner and outer rings. They enable the track roller to roll smoothly along the track, reducing friction and wear.

4. Seals and shields: Track rollers often have seals or shields to protect the rolling elements from contaminants, such as dust, dirt, and moisture. These protective features help prolong the lifespan and performance of the track roller.

5. Lubrication: Some track rollers are equipped with grease fittings or lubrication holes to facilitate proper lubrication. Lubrication is essential to reduce friction and heat generation, ensuring smooth operation and preventing premature wear.

FUNCTION

1. Load support: The main function of track rollers is to support and carry the weight of the machine or equipment they are installed on. They distribute the load evenly along the track, preventing excessive stress and ensuring the stability of the machine.

2. Guiding movement: Track rollers guide the linear or rolling motion of the machine along the track. They help maintain the alignment and prevent deviation, ensuring precise and controlled movement.

3. Reducing friction: By utilizing rolling elements, track rollers minimize friction between the machine and the track. This reduces energy consumption, prevents overheating, and increases efficiency and productivity.

4. Absorbing shock and vibration: Track rollers can absorb shocks and vibrations generated during operation, providing a smoother and more comfortable ride for operators and reducing the stress on the machine.

5. Enhancing durability: Track rollers are designed to withstand heavy loads, harsh environments, and continuous use. They are built with high-quality materials and undergo stringent manufacturing processes to ensure durability and reliability.

Overall, track rollers play a crucial role in the smooth and efficient operation of various machines and equipment that rely on linear or rolling motion. Their robust structure and precise function contribute to the overall performance and longevity of the systems they are integrated into.

RECOMMEND PRODUCTS

Other related hot products that may be of interest to you.

Track Shoe | Track Link | Upper Roller | Sprocket | Idler |

MORE PRODUCT RELATED VIDEOS

Reviews

There are no reviews yet.